• Easy installation

• Corrosion resistance

• Short construction period

• No maintenance required

• Light weight, no influence to original structure

• Low cost, cost effective compared with other methods

Advantages of CFRP Fabric• Easy installation |

|

• Flexible

• High strength

• High modulus

• Easy to install

• Long shelf life

• Light self weight

• High toughness

• Anti high temperature

• Environmental-friendly

• Carbon fiber wrap used for shear strengthening, confinement strengthening, flexural strengthening

|

Key Features of CFRP Wrap• Flexible |

• Aviation Grade Yarn

Japan imported aviation grade raw material, good quality and stable performance.

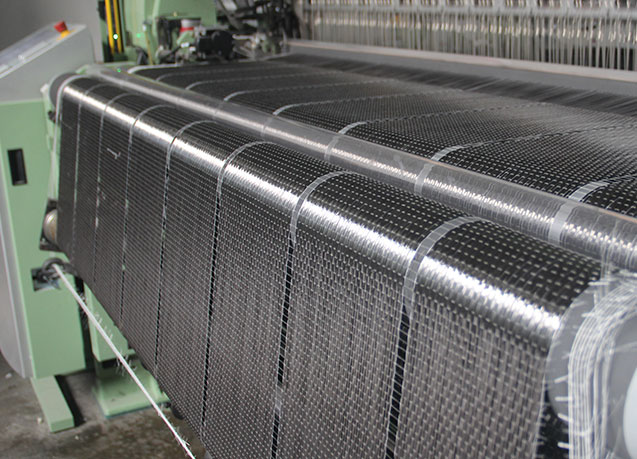

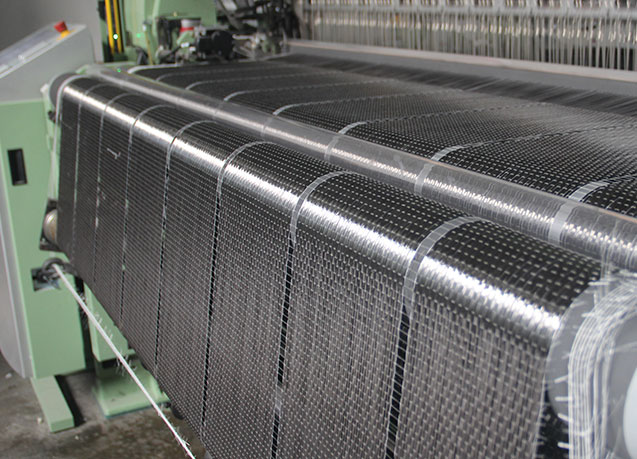

• Powerful Weaving Techniques

Excellent flatness enable epoxy easy to penetrate, hence high bonding strength can be achieved.

• Professional Facility

Germany imported weaving machine, large output, various width, stable quality.

• Full Strain, Use Full Strength of CFRP Wrap

Fiber state evenly, each fiber is under same stress, enable the even and stable property.

Manufacturer of CFRP Wrap• Aviation Grade Yarn • Powerful Weaving Techniques • Professional Facility • Full Strain, Use Full Strength of CFRP Wrap |

|

• Load increases

• Seismic reinforcement

• Improve structural state

• Damage of structural parts

• Change the structural function

• Remit mistakes in design and construction

|

Application Range• Load increases |

• Concrete substrate

• Steel substrate

• Masonry substrate

• Timber substrate

Base Substrates• Concrete substrate |

|

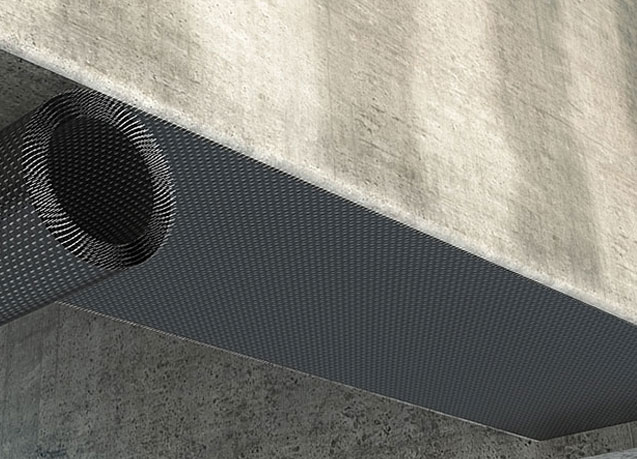

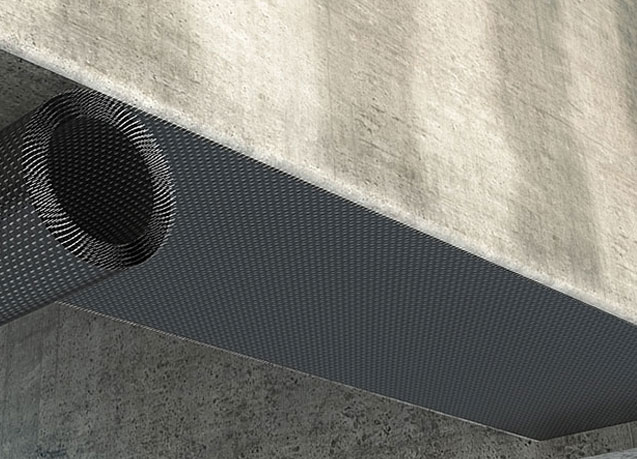

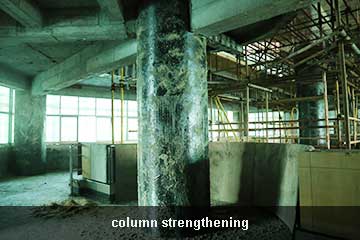

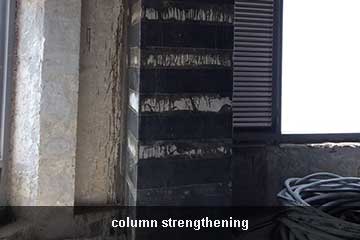

• Columns strengthening

• Beams strengthening

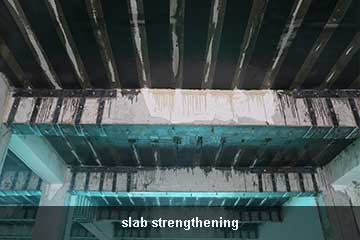

• Slabs strengthening

• Walls strengthening

• Pipes strengthening

• Pier caps strengthening

|

Structural Elements• Columns strengthening |

• Civil buildings

• Bridges

• Tunnels

• Piers/wharfs

• Airports

• Highways, railways

Construction Field• Civil buildings |

|

• Primer, for smearing of the underlayer of reinforced member’s surface

• Leveling adhesive, for repairing and leveling of reinforced substrate surface defects

• Impregnated adhesive, for impregnation and pasting of reinforced component surface and carbon fiber wrap

|

Best Matched Epoxy System• Primer, for smearing of the underlayer of reinforced member’s surface • Leveling adhesive, for repairing and leveling of reinforced substrate surface defects • Impregnated adhesive, for impregnation and pasting of reinforced component surface and carbon fiber wrap |

• Surface treatment

• Applying primer

• Leveling

• Applying carbon fiber adhesive

• Externally bonded carbon fiber reinforced polymer(CFRP) wrap

• Applying carbon fiber adhesive again

• Curing and protecting

How to Use CFRP Wrap• Surface treatment |

|

HM-20 Carbon Fiber Fabric TDS.pdf

HM-20 Carbon Fiber Fabric TDS.pdf

HM-30 Carbon Fiber Fabric TDS.pdf

HM-30 Carbon Fiber Fabric TDS.pdf

HM-60 Carbon Fiber Fabric TDS.pdf

HM-60 Carbon Fiber Fabric TDS.pdf

| Carbon Fiber Typical Data | ||

| Storage Condition | Store dry at 40°-95° F(4° -35°) | |

| Shelf Life | 50 years | |

| Color | Black | |

| Primary Fiber Direction | 0°(unidirectional carbon fiber wrap) | |

| Arear Weight | HM-20 carbon fiber wrap | 200g/㎡ (5.84 oz./sq.yd.) |

| HM-23 carbon fiber wrap | 230g/㎡ (6.72 oz./sq.yd.) | |

| HM-30 carbon fiber wrap | 300g/㎡ (8.76 oz./sq.yd.) | |

| HM-45 carbon fiber wrap | 450g/㎡ (13.14 oz./sq.yd.) | |

| HM-53 carbon fiber wrap | 530g/㎡ (15.48 oz./sq.yd.) | |

| HM-60 carbon fiber wrap | 600g/㎡ (17.52 oz./sq.yd.) | |

| Carbon Fiber Typical Fiber Properties | |

| Dry Fiber Typical Properties | |

| Standrad Value of Tensile Strength | 4900MPa |

| Tensile Elastic Modulus | 234500MPa |

| Elongation | 1.7% |

| Laminate Fiber Typical Properties | ||

| Standrad Value of Tensile Strength | 3800MPa | |

| Tensile Elastic Modulus | 234500MPa | |

| Elongation | 1.7% | |

| With Concrete | Concrete Damaged: ≥2.5MPa | |

| Densiy | 1.8g/cc(0.065lbs.in3) | |

| Norminal Fiber Thickness | HM-20 carbon fiber wrap | 0.111mm(0.0044in.) |

| HM-23 carbon fiber wrap | 0.128mm(0.0050in.) | |

| HM-30 carbon fiber wrap | 0.167mm(0.0065in.) | |

| HM-45 carbon fiber wrap | 0.251mm(0.0097in.) | |

| HM-53 carbon fiber wrap | 0.295mm(0.0114in.) | |

| HM-60 carbon fiber wrap | 0.333mm(0.0130in.) | |

Unidirectional black weaves carbon fiber wrapping (bidirectional carbon fiber cloth can be customized).

Regular width is 10cm, 15cm, 20cm, 25cm, 30cm, 50cm and 60cm.

Other width can be customized.

Carbon fiber wrap one roll length is 100m.

Carbon fiber reinforced polymer(CFRP fabric/wrap/sheet) for structural strengthening of column, beam, slab, wall

>>The treatment of concrete surface

The cosmetic layer, oil, dirt etc. Of concrete surface should be chiseled off and then rubbed off 1 ~2 mm thick surface layer with the angle grinder, concrete components should be handled by chamfering on the corner, dust was blew out with compressed air after the completion Of polishing, and finally the surface was wiped by cotton cloth dipped in acetone, and kept dry for use. If the concrete needed to strengthen existed cracks, first choose HM-120M perfusion adhesive or HM-120L pouring crack adhesive to perfuse according to the size of crack, and then strengthen.

>>Primer construction

When construction, two components of primer A and B were weighed according to the stipulated proportion of preparing glue, and dumped into a clean container and stirred to uniformity (when mixing, best mix along the same direction to avoid the air from forming air bubbles.) Brush or roller brush was used to evenly brush on the concrete surface, after the glue surface layer dried, it should be brushed several times depending on the particular circumstances, but the coating thickness did not exceed 0.4 mm, and it should not be missed out to brush, or have flowing or bubbles, waiting for glue curing (curing time was depended on the site temperature, it was appropriate when finger felt dry, generally not less than 2 hours), then the next process was proceeded. The glue prepared every time should be used up one time during the applicable period of the glue.

>>Leveling construction

The pores and defects on concrete surface were filled by leveling adhesive.When depression area was existed, the prepared leveling adhesive was used to repair and fill through scraper embedding and scraping, the position emerging altitude difference such as the joint of templates should be filled by leveling adhesive, which tried to minimize the height difference. The treatment of corner was that it was repaired to smooth arc through leveling adhesive, its radius was not more than 20mm. After the leveling adhesive cured (curing time was depended on the site temperature, it was appropriate when finger felt dry, generally not less than 2 hours), the next process should be proceeded further.

>>Paste of carbon fiber cloth

Carbon fiber impregnated adhesive was smeared to the pasted area evenly,the corner site was more smeared appropriately. Paste after hauling carbon fiber cloth tight and alignment, use a plastic scraper or roller (a paint roller that the villus was removed outside) to roll repeatedly along the same direction, until the glue compound exuded. And then smear impregnated adhesive to the outside surface of the carbon fiber cloth evenly, and roll repeatedly, 50 that the impregnated adhesive can immerse the carbon fiber cloth in two ways, if it is multi-paste, until your fingers touch dry, the next layer of paste can be beginner. If the carbon fiber cloth needs overlapping

>>Curing and conservation

Prevent rain or moisture 24 hours after the completion of construction, and pay attention to protection against a hard Object bumping into the surface of the construction. When the average air temperature is 20 , 25 ℃ , the curing time is not less than 3 days; when the average air temperature is 10 ℃, the curing time is not less than 7 days.