Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

One of the important factors to evaluate the quality of steel plate bonded reinforcement is the existence of empty drum.

The mechanism of the planting method is to drill holes in the surface of the original structure, and then implant the steel bars after injecting the chemical anchoring, so that the newly added structure and the original structure can be well combined into one whole and jointly stressed. Therefore, the performance of concrete substrates and cements is the most basic step in grasping the effect of planting.

Today, from the perspective of materials, Horse Construction analyzes the effects of planting tendons.

Influence of concrete strength on planting reinforcement engineering

Under the same conditions, the ultimate pull-out force of the planting bar increases with the increase of concrete strength. First, because the strength of the concrete increases, the adhesion between the binder and the concrete increases. Second, because the strength of the concrete will increase the phagocytosis between the binder and concrete, thereby improving the bond strength.

The concrete substrate should be solid and have a large volume and can withstand the pull-out force of the joint and all additional loads. The concrete strength grade of the substrate should not be lower than C20, and should not be higher than C60. The safety grade is the first stage anchorage connection, and the concrete strength grade of the substrate should not be lower than C30. Substrates with severe defects and low concrete strength grades have lower ultimate load carrying capacity. Therefore, in the case of weathered concrete, severely cracked concrete, and uncompacted concrete, when the margin of the planting bar is small, the concrete around the planting bar will undergo splitting damage.

The effect of planting anchoring adhesive

At present, there are many types and types of planting binders on the market, and their properties are different. They are divided into organic and inorganic types according to their chemical composition; they are divided into single-component and two-component implants according to the combination. Binder, including binder and curing agent mixture or separate composite binder; according to the construction method: tube-mounted, mechanical injection and on-site preparation of perfusion.

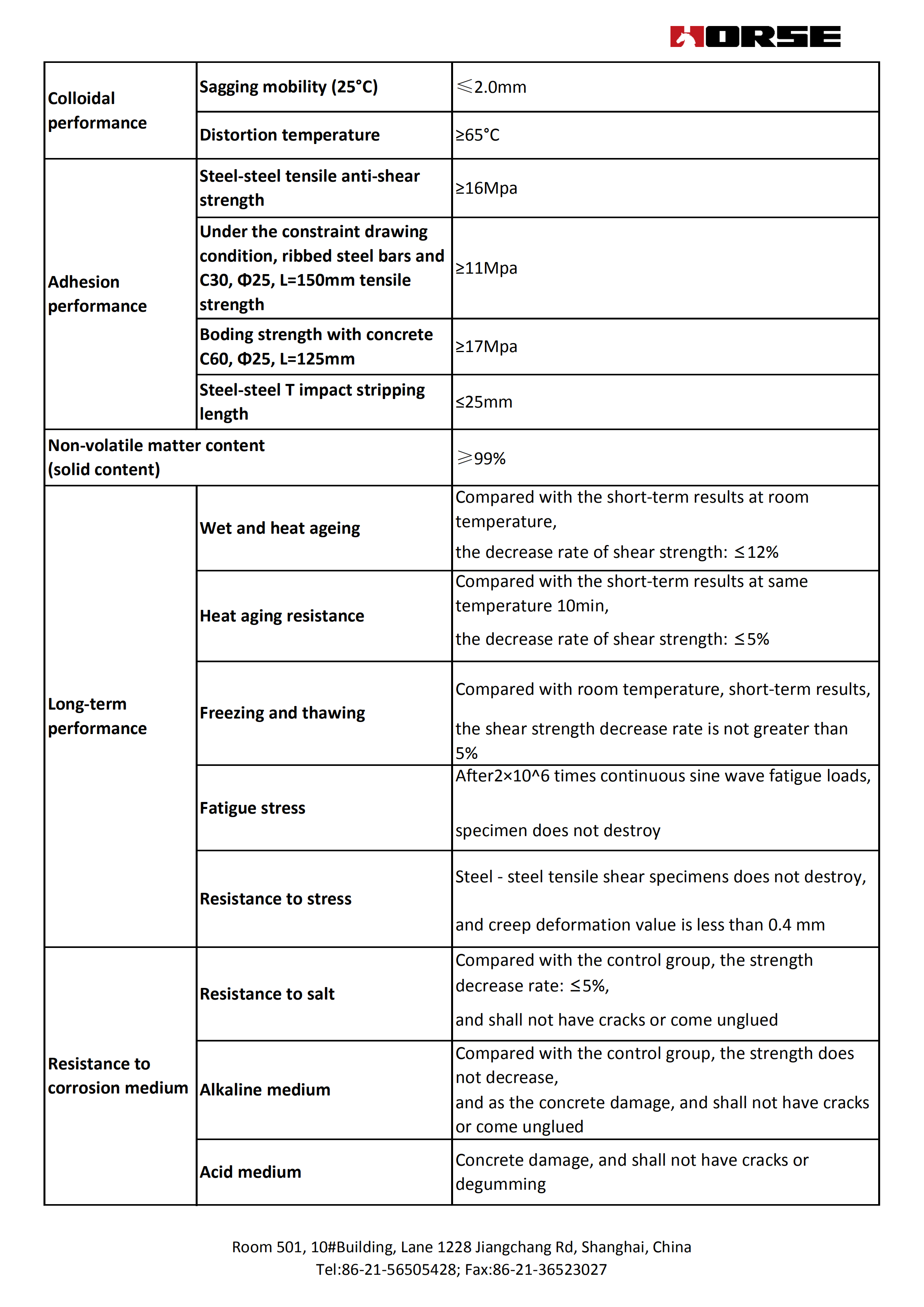

In practical construction applications, choosing a safe, reliable, stable quality and good performance adhesive is an important measure to ensure the quality of the project. Here, we will not list the types of planting rubber products on the market, and remind everyone that when selecting materials, we can refer to the parameters of the rubber planting rubber to ensure that the engineering requirements are met.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Thickness:1.2mm, 1.4mm, 2.0mm, 3.0mm

Density: 1.6g/cm³

Packing: 100 meters/roll

Width: 50mm, 100mm or to be custo

Manuel dispenser gun

Imported high quaility

Specially designed for 390ml HM-500 injectable epoxy anchor adhesive.