Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

The design, construction and inspection of CFRP reinforcement should be completed by a qualified team. Carbon fiber reinforcement will be more widely used in the reinforcement and reconstruction of building structures because of its own characteristics.

Carbon fiber reinforcement is suitable for reinforced concrete structural members. Fiber composite materials are used as reinforcement materials to bear loads directly. Adhesives are used as base materials in reinforcement to fix the role of carbon fiber and transfer loads.

1. Classification according to the technical methods and means used in reinforcement

Increasing section reinforcement method, steel enclosure reinforcement method, prestressing reinforcement method, changing the way of structural transmission reinforcement method, crack filling reinforcement method, bonding FRP reinforcement method, bonding steel reinforcement method, etc.

The bonding fiber reinforcement method is a direct reinforcement method which uses bonding adhesive to bond the fiber reinforced composite material to the concrete surface of the original component to form a composite section with integrity, so as to improve the bearing capacity and ductility. Fibers mainly include reinforced plastics, glass fibers, aramid fibers, carbon fibers and so on. The advantages of bonded fiber reinforcement method are similar to those of bonded steel plate reinforcement method. The construction method is relatively simple and has a wide range of applications. At the same time, it has the characteristics of corrosion resistance, moisture resistance, small self-weight increase, durability and low maintenance cost. It is suitable for the reinforcement of concrete structures with various mechanical properties and components of general structures. While maintaining the original structural state, it meets the requirements of owners for effective use space and appearance of buildings. The disadvantage is that the fiber material is linear elastic until it breaks, and it is brittle when it breaks. It should be avoided to reinforce the concrete members whose strength is lower than C20 grade, and special fire protection treatment is needed.

2. Force analysis

According to GB50367-2013, CFRP reinforcement is suitable for reinforced concrete flexural, axial compression, large eccentric compression and tension members. Its application mode is generally to paste CFRP on the surface of the tension zone, and the direction of the fiber is consistent with the direction of the tension. However, CFRP reinforcement is not suitable for plain concrete members, nor is it suitable for members whose longitudinal reinforcement ratio is lower than the minimum reinforcement ratio stipulated in the current national standard “Code for Design of Concrete Structures”. GB50010-2010. From the experience of practical engineering reinforcement, CFRP reinforcement can not significantly improve the bearing capacity of the structure, the flexural and shear bearing capacity of the beam is more direct, the shear bearing capacity of the column is also improved to some extent, but the improvement of the compressive and bending bearing capacity of the column is not obvious. The code GB50367 also specifies that the flexural capacity of reinforced concrete members should not be increased by more than 40% after reinforcement, and the shear capacity of normal sections should be checked to avoid the shear failure of members prior to flexural failure due to the increase of flexural capacity. If the bearing capacity of structural members is very poor, other reinforcement methods should be adopted. Therefore, in a comprehensive reinforcement project, several reinforcement methods are often combined to make the reinforcement of different concrete structural members achieve the best stress state.

3. Performance test of fibers and adhesives

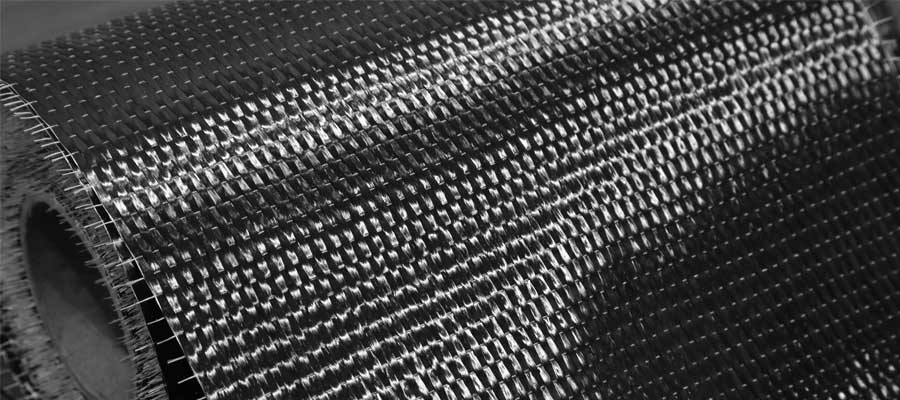

Because the fiber composite used for structural reinforcement bears load directly as reinforcement material, its quality will directly affect the safety effect of reinforcement and the engineering cost of reinforcement, and the carbon fiber contained in it is the fundamental measure of the quality of fiber composite material. Carbon fiber is a new material with light weight, high strength and high modulus of elasticity. Its specific gravity is 1/5 of iron, its strength is l0 times of iron, and its modulus of elasticity is close to steel. It has the properties of rust-free, acid-alkali-resistant and corrosion-resistant. X-ray transmission, heat resistance, low temperature resistance, unidirectional and so on. The fibers of the composite materials used for structural reinforcement must be continuous fibers. The varieties and properties of the composite materials and the safety performance indexes of the composite materials themselves must meet the requirements of the specification GB50367-2013. The quality of the carbon fibre fabrics per unit area must be strictly controlled and must be less than or equal to 300 g/m2.

Adhesives used in load-bearing structures, as the base material in reinforcement, fix carbon fibers and transfer loads, play a more important role. According to the basic performance, they can be divided into grade A and B adhesives. According to different stress conditions, they can choose to use grade A adhesives for important structures, cantilevered components and structural components under dynamic loads, and grade A or B adhesives for general structures. Safety performance test must be carried out for load-bearing adhesives. The standard value of bond shear strength should meet the requirements of confidence level c=0.90 and guarantee rate 95%.

4. The design, construction and inspection of CFRP reinforcement should be completed by a qualified team. Carbon fiber reinforcement will be more widely used in the reinforcement and reconstruction of building structures because of its own characteristics.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Weight: 600g/sqm

Thickness: 0.333mm

Density: 1.8g/cm³

Packing: 100 meters/roll

Width: 100mm, 200mm, 300mm, 500mm or to be cus

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

Barrel B Size: 25*25

Part A (Epoxy): 20kg

Part B(Hardener):10kg

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

Bar