Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

In recent years, the application of pre-stressed carbon plate reinforcement technology to long-span bridge structures has achieved good reinforcement results. As a vigorous promoter of pre-stressed carbon plate reinforcement technology, Shanghai Horse Construction has successfully applied this technology on many domestic high-speed bridges in recent years.

It is reported that the number of highway bridges in China has exceeded 800,000, and the cumulative length of high-speed railway bridges exceeds 10,000 kilometers. The total number of Yangtze River Bridges under Yibin alone, including those under construction, has reached 135. Bridges have become beautiful business cards built in China.

With the rapid economic growth and the rapid increase of traffic volume in China, a large number of bridges are operating under high load. Because of the long-term service environment (such as load, carbonization, freeze-thaw, chemical erosion, etc.), the concrete bridge structure will crack, the bearing capacity of the bridge will be reduced, the service life will be shortened, and even the collapse of the bridge will occur.

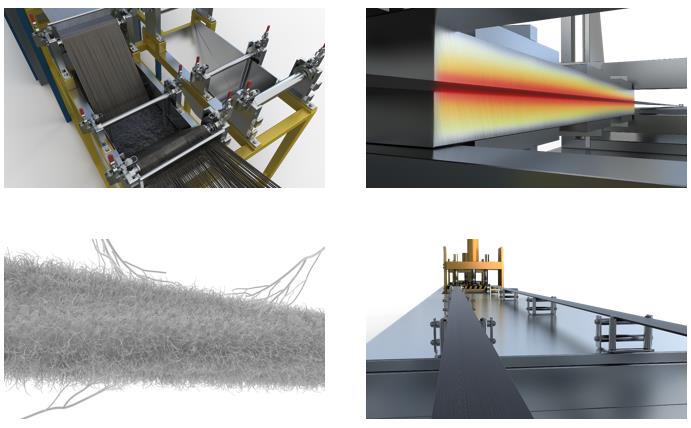

In recent years, the application of pre-stressed carbon plate reinforcement technology to long-span bridge structures has achieved good reinforcement results. As a vigorous promoter of pre-stressed carbon plate reinforcement technology, Shanghai Horse Construction has successfully applied this technology on many domestic high-speed bridges in recent years. Then, why can HM pre-stressed CFRP plate technology succeed in large-span structures such as bridges? What are its advantages over traditional reinforcement methods?

1. Effective reinforcement methods

Experiments show that concrete beams strengthened with ordinary concrete beams and ordinary carbon fiber sheets are prone to yield failure and peeling failure of reinforcing bars under strong external forces, while the bearing capacity of concrete beams strengthened with pre-stressed carbon fiber laminate is greatly improved. It can be seen that the strengthened reinforced concrete structure with pre-stressed carbon fiber laminate has obvious advantages.

Prestressed carbon laminate should be changed from passive reinforcement to active reinforcement.

(1) Let old and new components bear force together

(2)Give Full Play to the High Strength of CFRP

(2)Solving the stress lag phenomenon

2. Stable prestressed CFRP plate system

The elastic modulus of carbon fiber material is similar to that of steel bar, but its strength is five times that of steel bar. Therefore, when carbon fiber material exerts its strength, its deformation is larger. When steel bar yields or concrete is destroyed, the strength of carbon fiber has not been fully exerted. Prestressed carbon fiber reinforcement technology can better solve this problem and greatly improve the utilization rate of carbon fiber materials. Prestressed CFRP anchorage system can not only increase the strength and stiffness of the structure, but also reduce the deflection and deformation of the structure, but also reduce and seal the cracks.

Compared with the defects of easy rust corrosion, electrode corrosion, thermal expansion and contraction, bending stress loss and cumbersome construction, the prestressing carbon fiber sheet system shows a strong reinforcement advantage. It has the characteristics of acid-alkali-salt resistance, stable performance of carbon fiber, good long-term performance of glue, low stress loss and convenient construction, and is a more stable pre-stressed reinforcement system.

3. Advanced anchor design

1. The reasonable inclination angle, the tooth profile angle, the tooth profile depth and the length direction of the tooth profile extension splint are adopted to make the contact between the splint and the carbon fiber sheet more close and firm, which overcomes the common problems of sliding and splitting of the carbon fiber sheet in the tension process.

2. The anchor frame adopts the integral stamping forming process, which has high overall strength and avoids the problem of insufficient strength and uneven distribution of stress in weld.

3. The high precision wire cutting technology is used for the channel and clip of anchor block, and the error is controlled within 0.1 mm. The actual stress condition is in good agreement with the theoretical analysis, so as to ensure the tension effect.

4. The splint and anchor block are cut in one piece, and the number of the splint and the anchor block correspond one by one, so as to realize the excellent fit and adaptability of the interface between the anchor block and the splint, and ensure the uniform force.

5. Using split design, the parts are packaged and transported separately, and the replacement is simple.

6. Fixed anchor bolt is used to fix anchor block and anchor frame to overcome the influence of bending moment caused by eccentric tension eccentricity on the whole system.

7. Only slotting the location of anchor block, slotting depth and slotting area are small, which can reduce the damage degree to the original component.

8. The cutting length of CFRP can be adjusted flexibly according to the site conditions by means of on-site installation, so as to avoid the disadvantage that the integral anchorage can not change the length of CFRP.

9. Installation of components is simple, except anchor frame, anchor block and clip, the other components are standard parts; at the same time, various tooling for installation is provided to simplify the construction process.

4. Perfect prestressing solution

Have you encountered the following six problems in the reinforcement of prestressing carbon plate?

1. Insufficient prestressing tension

2. Anchors are too heavy and difficult to install.

3. Complex operation and long time

4. Carbon plate length needs to be customized

5. Destruction of concrete structures

6. poor durability

5. Stable carbon fiber quality

carbon fiber strip factory

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

Barrel B Size: 25*25*2

Two batteries, each one 4800 mAh

6 Speed mode

Portable design

Best for Large scale anchoring

Prestressed CFRP System(Post-tension CFRP system) includes anchoring devices and CFRP strip specially designed for bridge or lo