Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

Carbon fiber U stirrup in construction than the other anchoring method is much more convenient, light weight, corrosion resistance, anchorage range, wide application scope, anchoring method most commonly used carbon fiber U shaped carbon fiber reinforced hoop is still in.

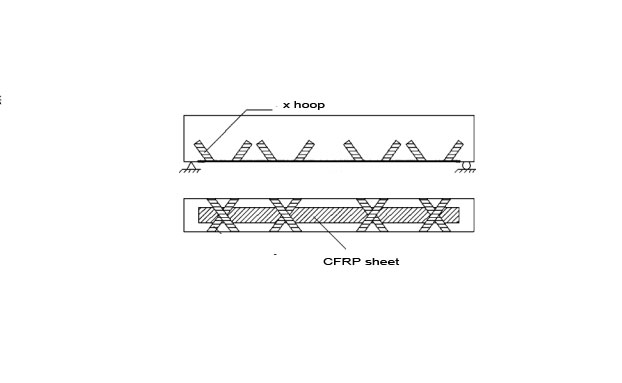

1. Comparison between U hoop anchor and additional anchor bolt anchorage at bottom of beam

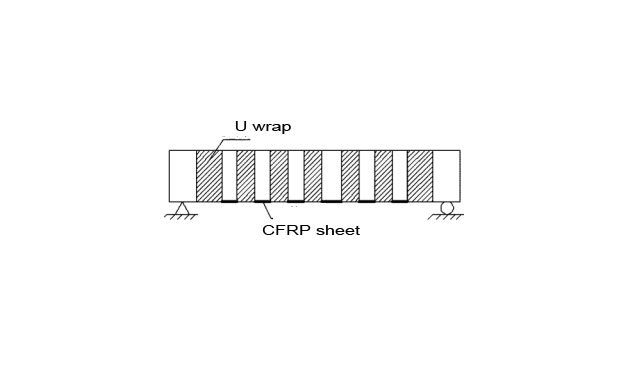

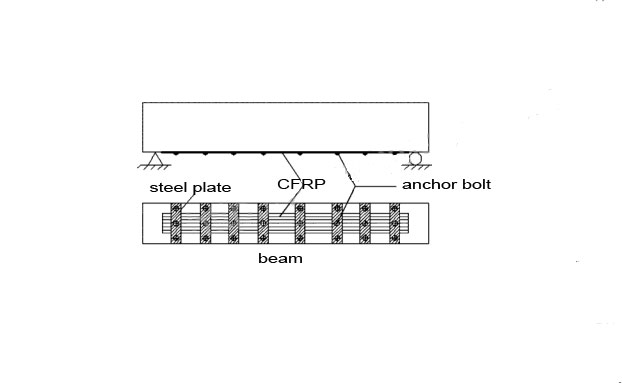

In the flexural strengthening of CFRP sheets, U type hoop anchorage or additional anchor bolts at the bottom of the beam can be adopted.

According to previous experiments, it can be known that when the carbon fiber cloth begins to peel off and meets the anchor bolt when peeling, the anchor bolt is quickly crossed and the restraining effect of the anchor bolt is almost not felt. This is because there is a certain diameter difference between the expansion bolt and the perforated hole. When the carbon fiber cloth is peeled off, the carbon fiber cloth will pull the anchor bolt to produce lateral deformation. When a certain lateral deformation is achieved, the shear resistance of the anchor bolt can be brought into play. It can be said that the effect of anchor bolt on restraining the stripping of CFRP is not obvious, and when the stripping develops to a certain extent, the anchor bolt can restrain the overall slip of CFRP. Therefore, compared with the U hoop, the anchorage effect of the additional anchor bolts at the bottom of the beam is weaker.

2. Comparison between steel plate U hoop anchor and carbon fiber U hoop anchor

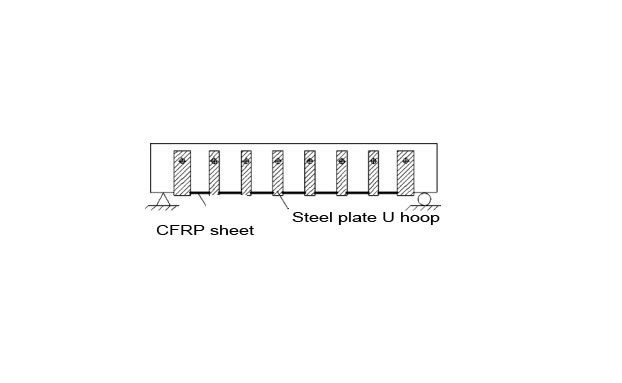

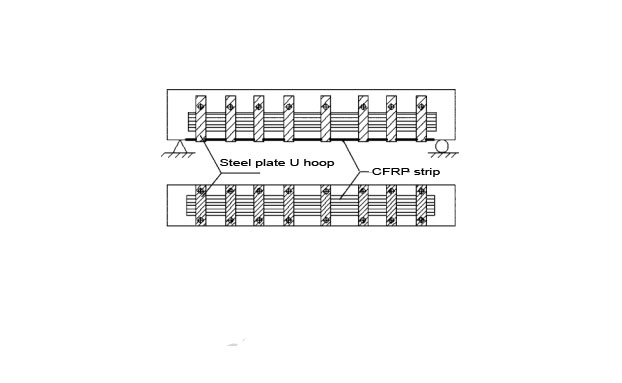

Steel plate U-hoop anchorage is a rigid anchorage scheme, while carbon fiber U-hoop anchorage or other forms of carbon fiber anchorage are flexible anchorage schemes. For the flexible anchorage scheme using CFPR sheets, the stress of CFPR sheets near cracks at dangerous sections increases rapidly, resulting in higher concentrated stress. The stress of the fiber sheet near the dangerous section is also increased. With the increase of load (crack width increasing), the fiber sheets at the anchorage gradually show strip tearing. At last, the fiber sheets adhering to the beam side and the remaining anchorage sheets in the anchorage zone are all peeled off instantaneously, and the reinforcement components are damaged. The rigid anchorage scheme is obviously superior to the flexible one. Because of the material characteristics, the strip tear of steel plate U-hoop will not occur like carbon fiber U-hoop, so the rigid anchorage method can better solve the anchorage problem of CFPR sheet at the joint.

In addition, the rigid anchorage scheme of steel U-shaped hoop is often used to reinforce low-strength concrete members with carbon fiber sheets, which will get better anchorage effect. Because in a certain range of concrete strength, the bond strength is controlled by the strength of concrete. The lower the strength of concrete, the lower the bond strength between them, and the easier the peeling occurs. The test proves that the CFRP reinforcement method can be used to reinforce low strength concrete beams when the U-shaped hoop of steel plate is used as additional anchorage measure, and the bearing capacity of the strengthened beams is greatly improved.

In the reinforcement of bonding carbon fibre sheet, because carbon fibre sheet is much thicker than carbon fibre sheet, if we use carbon fibre U-hoop anchorage, one layer is often not enough, so we need to bond multi-layer to have better anchorage effect. The U-shaped hoop bonded with multi-layer carbon fibers has some problems, such as impregnated adhesive layer is not easy to penetrate and construction is inconvenient, so the use of steel U-shaped hoop can achieve better anchorage effect, which is often a better choice. And obviously, because of the unidirectional force performance of carbon fiber material, the force performance of steel plate U-shaped hoop is obviously better than that of carbon fiber U-shaped hoop at the corner of U-shaped hoop.

However, the U-shaped hoop of steel plate used for anchorage is generally thin, easy to corrode, affecting the service life, so it should be protected, which increases the complexity of construction. Moreover, the weight of steel plate is larger than that of carbon fiber material, forming is more difficult than that of carbon fiber U-shaped hoop, the requirement for bonding surface is higher, the construction is not convenient, it is difficult to ensure that the three sides coincide with the reinforced components accurately, and it is difficult to ensure the quality of bonding, which is inferior to carbon fiber U-shaped hoop.

3 Comparison between carbon fiber X hoop anchoring and carbon fiber U hoop anchor

Compared with other anchorage methods, carbon fiber U-shaped hoop anchorage has many inherent features which are different from other anchorage methods, but its application in current engineering is more common than other anchorage methods. Because carbon fibre U-shaped hoop is much more convenient than other anchorage methods in construction, lighter in weight, less corrosive and wider in Anchorage range. In view of the weakness of unidirectional mechanical properties of carbon fiber materials, the method of two-way or multi-direction bonding carbon fiber cloth can be used to solve this problem.

4 Conclusion

(1) the bolt anchoring effect is not as good as the U shape hoop. U shaped plate hoop is a rigid anchoring scheme for flexible scheme compared with various forms of carbon fiber anchoring, anchoring effect can play better, especially the strengthening effect of low strength concrete component is more obvious, but on the steel plate protection, and in construction than carbon fiber U hoop trouble. The stress mechanism of carbon fiber X ferrule better tensile strength of carbon fiber, and the anchoring effect U stirrup is mainly achieved by bonding properties and colloid to smaller peeling stress resistance. In comparison, the anchoring effect of the X hoop is obviously stronger than that of the U hoop. However, the probability of intersection of X hoop and oblique crack is smaller than that of U hoop.

(2) the carbon fiber U stirrup in construction than the other anchoring method is much more convenient, light weight, corrosion resistance, anchorage range, wide application scope, anchoring method most commonly used carbon fiber U shaped carbon fiber reinforced hoop is still in. The carbon fiber single direction stress performance of this weakness, can adopt bidirectional or multidirectional CFRP this method to solve.

(3) beam side constraints layering, can limit the diagonal crack to the development, improve the bearing capacity of beam, enlarge the compression area of concrete compression zone. The beam has better ductility and the integrity of the U hoop can also be strengthened. Therefore, there are additional beams on the side of the beam, and the anchoring effect will be better.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Consumption Ratio: 6-7kg/sqm

Bar

Part A (Epoxy): 20kg

Part B(Hardener):10kg

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

Bar

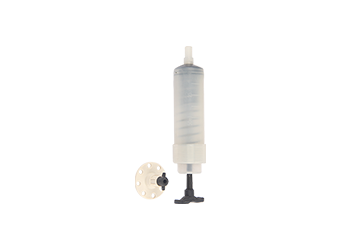

Volum: 75ML

Epoxy injctor is the tool to inject the epoxy into the crack.