Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

Comparing various reinforcement schemes, all parties agree that the method of carbon fiber reinforced polymer(CFRP) wrap bonding is the most appropriate. From the actual use of the situation, the results are good.

Preface

In the renovation project of a building, due to the change of building function, six bidirectional slabs are required to cut off part of them for the opening of the elevator, so that the original bidirectional slabs are changed into one-way slabs. Due to the completion of the structural reinforcement, the overall renovation is still needed, and the construction period is very tight. Owners have higher requirements on the effective use space of buildings, the impact surface of construction, the durability and appearance of reinforcement materials. Comparing various reinforcement schemes, all parties agree that the method of CFRP bonding is the most appropriate. From the actual use of the situation, the results are good.

Carbon fiber reinforcement is a reinforcement method in which carbon fiber sheets are glued to the surface of concrete members to improve the bearing capacity of the structure. The method has the advantages of wide application, no influence on the shape of the structure, good durability and corrosion resistance, simple and fast construction, etc. The main function of carbon fibre sheet is to resist tension. It is generally used in the tension parts of slabs and beams of flexural members, shear parts of beams and columns (piers), reinforcement of columns or piers and insufficient length of reinforcing bars.

Carbon fiber reinforcement principle

Carbon fibers are very fine fibers. Because of their high strength, they have high tensile strength in the direction of fibers when they are combined by epoxy resin. In the reinforcement design of structures, it is generally avoided that two kinds of materials with different properties are combined together. Although the strength of carbon fibers is very high (about 10 times that of steel bars), the elastic coefficient of carbon fibers is similar to that of steel bars, as shown in Table 1. There will be no mismatch in the reinforcement of reinforced concrete with carbon fibers, so it can be used to make up for the insufficient tension of reinforcing bars in reinforced concrete. Carbon fiber reinforced structure belongs to secondary composite structure, and as the bonding force between steel bar and concrete is general, carbon fiber needs to be combined with cement and concrete, and the combination between them must be greater than the shear strength of concrete itself. This kind of adhesive is applied on the flat surface of concrete, commonly known as the bottom resin. It is easy to penetrate into concrete and combine with concrete to form resin-like concrete. It can strengthen the strength of concrete and combine closely with carbon fibers to effectively transfer shear force, so that carbon fibers and concrete can be combined to achieve reinforcing effect. .

| Concrete | A steel bar | Carbon fiber | |

| Elastic coefficient(Gpa) | 2.5 | 200 | 230 |

| Strength(Gpa) | 20 | 300-400 | 3000-3500 |

| Ductility | 0.2-0.3% | 0.2-0.3% | 0.9-1.5% |

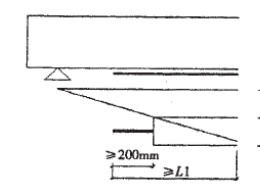

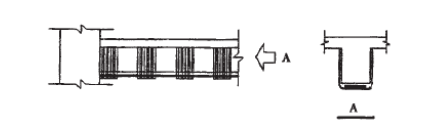

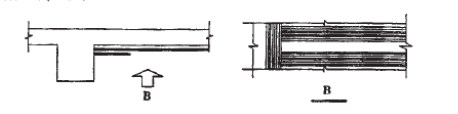

Extension length of carbon fiber material

Extension length of carbon fiber material

For beam, carbon fiber U wrap additional anchoring measures are adopted in the extension length of carbon fiber sheet.

For the slab, the layering of the carbon fiber in the direction of the carbon fiber sheet is stretched.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Part A (Epoxy): 20kg

Part B (Hardener): 1kg

Mix Ratio: Part A: Part B=20:1

Barrel A Size: 30*30*37cm

Barre

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

Barrel B Size: 25*25*2

Weight: 600g/sqm

Thickness: 0.333mm

Density: 1.8g/cm³

Packing: 100 meters/roll

Width: 100mm, 200mm, 300mm, 500mm or to be cus