Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

In fact, in addition to the different modes of stress, the selection of concrete column reinforcement scheme is related to multiple factors. The scheme selection should also take into account the specific characteristics, technical and economic conditions of the original structure.

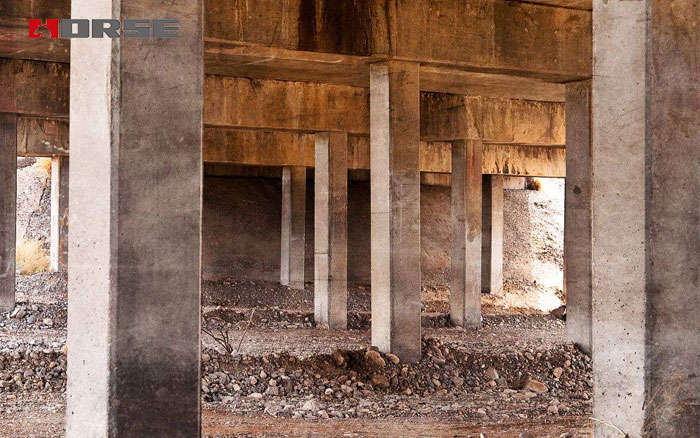

Reinforced concrete has been widely used in various engineering structures because of its high bearing capacity and durability. The failure modes of reinforced concrete structures with different components are different. In structural reinforcement, each reinforcement method has its unique scope of use and advantages and disadvantages. Therefore, understanding the stress system of members is a necessary prerequisite for selecting a reasonable reinforcement method.

Reinforced concrete columns, which belong to typical compression members, are important load-bearing members in building structures. In the actual use process, due to the difference of the distribution of the upper load, the actual stress state of the column can also be divided into axial compression, small eccentric compression and large eccentric compression, which should be treated separately in the reinforcement.

Axially loaded reinforced concrete column

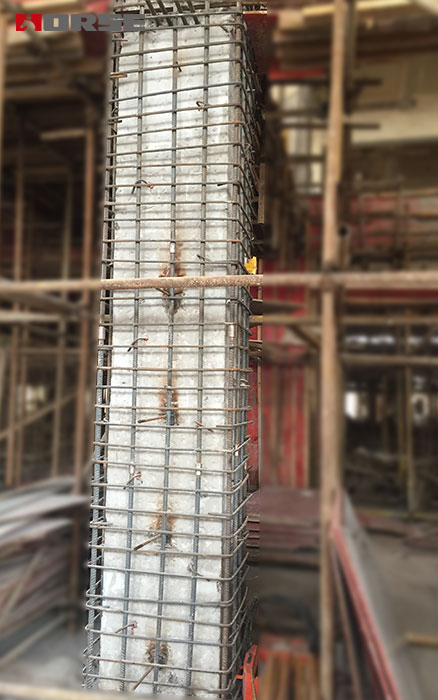

The axial compression members only bear the axial force of the center of the section. In the process of bearing increasing load, the concrete will expand transversely when it is subjected to excessive axial pressure. The tensile stress produced by expansion will eventually exceed the tensile strength of concrete, resulting in brittle failure of concrete. Axial compression column can be strengthened by composite section, and it can also restrain the deformation of concrete laterally. The reinforcement effect can be achieved by similar stirrups.

The use of circumferential girding to reinforce axially loaded members can only be applied to the following situations:

Circular section column with slenderness ratio l/d less than or equal to 12

The slenderness ratio l/d is less than or equal to 14, the section height ratio h/b is less than or equal to 1.5, the section height h is less than or equal to 600 mm, and the section edges are rounded and polished square or rectangular columns.

Axial compression columns can be strengthened by increasing the section area or reinforcement ratio to enhance the bearing capacity and stiffness, and the angle steel and the column can be strengthened by external bonded steel to form an integral force to enhance the bearing capacity and seismic performance. In addition, CFRP can be used to restrain the deformation of concrete with circumferential girders, and the bearing capacity can be strengthened indirectly. It should be noted that there are different application ranges between circular and square columns, and the restraint effect of CFRP beyond the range will be significantly reduced, which is not suitable for use

Small eccentrically loaded columns

The stress state of the columns subjected to small eccentric compression is similar to that of the flexural members, and the failure mode is similar to that of the beams subjected to bending. The failure of columns with small eccentricity is due to the fact that the compressive strength of concrete exceeds the compressive strength in the compressive zone, while the reinforcement on the other side generally fails to yield. This kind of failure is not obvious and has brittle failure, so the concrete strength in the compression zone should be considered to meet the use demand.

In small eccentric compression, enlarged section reinforcement method and external bonded steel reinforcement method can still be used to enhance the compressive capacity of columns. However, CFRP sheet can not exert its high strength when it is bonded to the tensile side of columns under small eccentric compression, and can not exert its effect on the concrete in the compression zone, so it is not suitable for the columns under small eccentric compression.

Large eccentric compression column

When the bearing capacity of large eccentrically loaded columns is insufficient, the yield failure of steel bars will occur easily. When the column is destroyed by large eccentric compression, the steel bar on the tension side yields first, and then the concrete on the compression side is destroyed. The destroying process has obvious foreboding, and the degeneration is bigger, so it is an ideal destroying form. The bearing capacity of this kind of column mainly depends on the tensile strength of the tensile side, and it can be strengthened by increasing the tensile strength of the tensile side.

When strengthening the columns with large eccentricity, the method of increasing section and strengthening with externally bonded steel plate can be adopted. On the other hand, in large eccentric compression columns, the strain on the tension side is transformed from the compression side, so it can give full play to the advantage of high tensile strength of CFRP. In order to improve the strength of concrete on the tensile side, CFRP should be bonded to the surface of concrete along the longitudinal axis of the column.

In fact, in addition to the different modes of stress, the selection of concrete column reinforcement scheme is related to multiple factors. The scheme selection should also take into account the specific characteristics, technical and economic conditions of the original structure, according to the specific inspection and appraisal results, select the reinforcement method which has less disturbance to the original structure and is convenient for construction, and adopt the reinforcement material which has passed the safety appraisal to reinforce the construction. The choice of reinforcement method is directly related to the reinforcement effect, and needs to be chosen in combination with reality.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Part A (Epoxy): 20kg

Part B (Hardener): 1kg

Mix Ratio: Part A: Part B=20:1

Barrel A Size: 30*30*37cm

Barre

Type: HM-500

Volume: 390ml

Mix Ratio: 3:1

Color: Red or Black

Density: 1.5±0.1g/cm³

Packin

Two batteries, each one 4800 mAh

6 Speed mode

Portable design

Best for Large scale anchoring