Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

Reinforcement of reinforced concrete members with embedded prestressed FRP plates can significantly improve the mechanical properties of reinforced concrete members, and its mechanism and effect are similar to that of external prestressed FRP plates.

Surface embedded FRP plate reinforcement technology

The surface embedded FRP plate reinforcement technology can combine the advantages of NSM technology and external bonded prestressed FRP technology to better solve the problems of interface peeling and material strength utilization. At the same time, it is possible to use the bonding ability between FRP and concrete to realize the anchorage of prestressed FRP plates, thus canceling the permanent anchorage setting required for external bonding of prestressed FRP sheets and reducing the cost of structural reinforcement. However, because NSM technology is to embed FRP slab in the concrete protective layer outside the steel bar with binder, how to realize the anchorage and tension of FRP slab in the limited thickness space becomes one of the key problems of this technology.

The concrete technology of surface embedding prestressed FRP plate to reinforce concrete structure is:

1) Grooving is needed on the surface of concrete structure where the FRP board is embedded, and the loose concrete around the grooving is chiseled and repaired.

2) install FRP plate clamp and tension machine at the end of concrete slot.

3) remove the water, oil and cement dust from the tank and fill the tank with adhesive.

4) FRP slats are embedded in the slot and anchored to the end of the fixture for tensioning.

5) After the tension is finished, the fixture fixed to the structure is used to anchor continuously. After the binder solidifies to the bonding strength, the FRP plate clamp is removed.

Using the self-developed FRP plate clamp, tensioning equipment and the above-mentioned technology, the author has strengthened several concrete flexural members by using the surface embedded prestressed FRP plate technology. Because the initial test is limited by the length of the structure, this paper does not fix the FRP clamp on the concrete members, but fixed on the tension platform at both ends of the members. But the size of the clamp used in this paper is designed to realize the tension in the thickness space of the concrete protective layer. The next step is to complete the equipment and process test on the large-scale components.

Test scheme

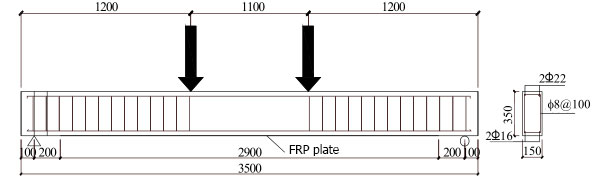

Five reinforced concrete flexural specimens were tested in this paper. All specimens were reinforced concrete rectangular beams with a total length of 3 500 mm. The effective span was 3 300 mm and the shear span was 1 100 mm. The section size of the specimen is 150mm * 350mm, and the reinforcement in the tension area is 216. In order to avoid cracking in the compression zone during prestressing, the reinforcement in the compression zone is 222, and the stirrups are only arranged in the shear span section, which is 8@100.

Five specimens consisted of one unreinforced comparative specimen, one specimens strengthened with ordinary (non-prestressed) surface embedded FRP, one specimens strengthened with external prestressed FRP, and two specimens strengthened with surface embedded prestressed FRP. The design strength of specimen concrete is C30. The surface embedded reinforcement specimens are strengthened by Horse Construction’s 500 CFRP strip, and the external strengthened specimens are strengthened by Horse Construction’s CFRP plate. The bonding resins are all made of Horse Construction’s carbon fiber board resin.

Main test results and analysis

1) bearing capacity analysis.

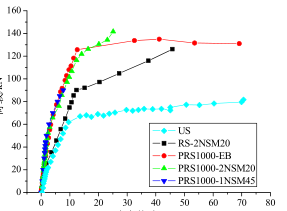

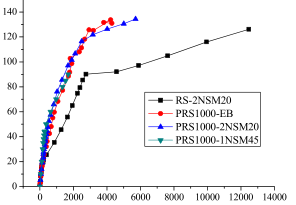

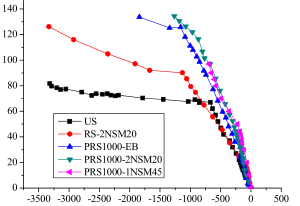

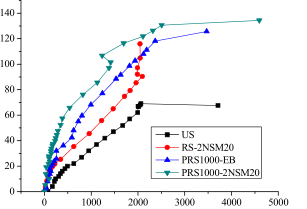

From the mechanical properties of the specimens depicted in Fig. 11-14, FRP reinforcement has a significant effect on the bearing capacity of the specimens. The yield load of RS-2NSM20 specimens strengthened by embedding non-prestressed surface layer was significantly greater than that of US specimens, but the effect of improving the mechanical properties of the FRP specimens was further enhanced after prestressing. The cracking load, yield load and ultimate load of PRS-EB and PRS-2NSM20 were significantly higher than those of RS, and the deformation of PRS-EB and PRS-2NSM20 under the same load was significantly smaller than that of non-prestressed specimens. The specimens PRS-1NSM45 suffered from early interfacial peeling failure before the main tendons yielded. The improvement of load-carrying capacity of the specimens was not fully embodied. However, as can be seen from Fig. 11, the relationship curves of PRS-1NSM45 before failure almost coincide with PRS-EB and PRS-2NSM20, and the cracking loads (PRS-EB:38kN, PRS-2NSM20:42kN, PRS-1NSM45:38kN) and yield loads (PRS-EB:125.7kN, PRS-2NSM20:126.3kN) are also very close. In view of the small difference between the initial stress and cross-section area of CFRP in the three specimens, this shows that the effect of surface embedded prestressed FRP reinforcement is similar to that of external bonded prestressed FRP reinforcement without interface peeling and protective layer tearing.

Curves of load versus mid-span deflection of specimens

Curves of load versus CFRP strain

Curves of load versus compressive strain of concrete

Curves of load versus tensile strain of rebar

2) failure mode analysis.

In this paper, the failure modes of the surface embedded reinforcement specimens are summarized. The failure of RS-2NSM20 is the peeling failure of the adhesive resin-concrete interface, and PRS1000-2NSM20 is the tearing failure of the main component-protective layer concrete. The failure mode of PRS1000-1NSM45 is that the resin-concrete interface peeling failure develops into the main component-protective layer concrete tearing failure. From the test results, it can be seen that the weak link of the non-prestressed surface embedded reinforcement members is the resin-concrete interface bond stress, while the same parameters of the prestressed embedded reinforcement members is the tensile strength of concrete, the introduction of prestress leads to the change of the failure control factors of the reinforced members. It is noteworthy that the maximum strain of the CFRP slab of the non-prestressed and prestressed strengthened specimens is almost the same (considering the initial strain of the prestressed CFRP slab). There are two possibilities for this phenomenon:

1) the control factors of the two reinforcement components are very close to the interface bond and the ultimate tensile strength of concrete.

2) The deformation of the specimens strengthened by non-prestressing is much larger than that of the specimens strengthened by prestressing. The failure modes of PRS1000-1NSM45 specimens indicate that the surface-embedded prestressed CFRP reinforcement technology must adopt other effective anchorage measures to ensure that the end-bonding stress is sufficient to resist the tensile stress of CFRP slabs in service without using end permanent anchorage. At the same time, the size, spacing and thickness of concrete groove should satisfy certain structural conditions to avoid the tear damage of concrete protective layer.

3) deformation capacity analysis.

The deformation capacity of components is an important index of structural performance. From the above figures, it can be seen that the RS-NSM and PRS-EB of the non-prestressed specimens have achieved great deformation (RS-2NSM 20:45.785mm, PRS-EB:69.14mm), but the failure deflection of PRS-2NSM 20 is only 25.1mm, while PRS-1NSM 45 is only 8.746mm, which is much smaller than other specimens. This is related to the failure mode of the surface embedded FRP slab. On the other hand, the CFRP strain and the compressive strain of the concrete near the ultimate compressive strain are 12466, while the compressive strain and CFRP tensile strain of PRS-EB are much smaller. This is due to the early appearance of FRP-concrete interfacial detachment of PRS-EB, but because of the installation of a strong mechanical anchor at the end, the specimens after detachment did not immediately lose the load-bearing capacity, and continued to deform until eventually CFRP was broken. It can be seen from the test in this paper that whether the ductility of the strengthened members embedded with prestressed FRP slabs meets the requirements is an important issue worthy of attention.

4 Conclusion

In this paper, five reinforced concrete flexural members strengthened by surface embedded prestressing FRP are tested and the following conclusions are obtained:

(1) The bonding area of FRP can be increased by embedding technology, and the anchorage of prestressed FRP plate can be realized by resin bonding ability, thus the permanent mechanical anchorage can be cancelled.

(2) Reinforcement of reinforced concrete members with embedded prestressed FRP plates can significantly improve the mechanical properties of reinforced concrete members, and its mechanism and effect are similar to that of external prestressed FRP plates.

(3) The failure modes of the surface-mounted reinforced members are the peeling off of the bonded resin-concrete interface and the tearing of the main body-concrete protective layer. The above failure modes show brittle characteristics and lead to premature failure of the prestressed reinforced specimens before the full strength of the material is exerted. The structural measures of bonding ability and restraining the tear of concrete cover are further studied.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Type: HM-500

Volume: 390ml

Mix Ratio: 3:1

Color: Red or Black

Density: 1.5±0.1g/cm³

Packin

Weight: 200g/sqm

Thickness: 0.111mm

Density: 1.8g/cm³

Packing: 100 meters/roll

Width:100mm, 200mm, 300mm, 500mm or to be custo

Weight: 600g/sqm

Thickness: 0.333mm

Density: 1.8g/cm³

Packing: 100 meters/roll

Width: 100mm, 200mm, 300mm, 500mm or to be cus