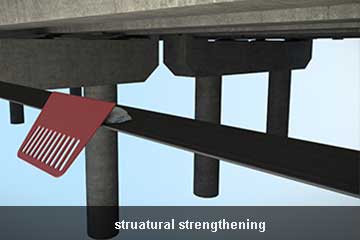

• Short construction period

• No maintenance required

• Easy installation, low installation cost

• Light weight, no influence to original structure

• Corrosion resistance, long-term effect of 50 years

• Cost effective compared with other retrofitting method

• 1 layers of CFRP plate is equivalent to 4-8 layers of CFRP fabric

Advantages of CFRP Plate Strengthening• Short construction period |

|

• High strength, high modulus

• Light weight

• Easy to install

• Easy to check after construction

• Environmental friendly

• Outstanding fatigue resistance, alkali resistance, acid resistance

|

Key Characteristics of CFRP Strip• High strength, high modulus |

• Special formula, make epoxy resins and carbon fiber are compound sufficiently.

• Intelligent automatic temperature control system, make the carbon fiber and epoxy resin heat evenly and curing sufficiently in mould cavity.

•Independent carbon fiber tow tension constant yarn shelf and large-tonnage hydraulic traction system, ensure every carbon fiber is glabrous before into the mould cavity and without broken after it out from the mould cavity. Keep tension, temperature, speed seriously to ensure the laminates more smooth and straighter.

• Intelligent stress control system, make the carbon fiber evenly distribute before or after the mould cavity, maximum avoid the stress of carbon fiber laminates after forming

Manufacturer of CFRP Strip• Special formula, make epoxy resins and carbon fiber are compound sufficiently. • Intelligent automatic temperature control system, make the carbon fiber and epoxy resin heat evenly and curing sufficiently in mould cavity. •Independent carbon fiber tow tension constant yarn shelf and large-tonnage hydraulic traction system, ensure every carbon fiber is glabrous before into the mould cavity and without broken after it out from the mould cavity. Keep tension, temperature, speed seriously to ensure the laminates more smooth and straighter. • Intelligent stress control system, make the carbon fiber evenly distribute before or after the mould cavity, maximum avoid the stress of carbon fiber laminates after forming |

|

• Load increases

• Seismic reinforcement

• Improve structural state

• Damage of structural parts

• Change the structural function

• Remit mistakes in design and construction

|

Application Range• Load increases |

• Beams strengthening

• Slabs strengthening

• Walls strengthening

• Pipes strengthening

• Pier caps strengthening

Structural Elements• Beams strengthening |

|

• Concrete substrate

• Steel substrate

• Masonry substrate

• Timber substrate

|

Base Substrates• Concrete substrate |

• Civil buildings

• Bridges

• Tunnels

• Piers/wharfs

• Airports

• Highways, railways

Construction Field• Civil buildings |

|

HM-120CP carbon fiber plate adhesive, designed for HORSE carbon fiber plate.

|

Best Matched Epoxy SystemHM-120CP carbon fiber plate adhesive, designed for HORSE carbon fiber plate. |

• Setting out according to design

• Polish the surface of concrete surface

• Prepare ingredients

• Applying adhesive

• Installation the carbon fiber strip

• Maintenance

How to Use CFRP Laminate• Setting out according to design |

|

HM CFRP Plate’s Date Sheet

![]() HM-1.2T Technical Data Sheet.pdf

HM-1.2T Technical Data Sheet.pdf

![]() HM-1.4T Technical Data Sheet.pdf

HM-1.4T Technical Data Sheet.pdf

| Item | HM-1.2T Carbon Fiber Laminate | HM-1.4T Carbon Fiber Laminate | HM-2.0T Carbon Fiber Laminate | HM-3.0T Carbon Fiber Laminate |

| Thickness(mm) | 1.2 | 1.4 | 2.0 | 3.0 |

| Length(m) | 100 | 100 | 100 | 100 |

| Width(mm) | 50、100 | 50、100 | 50、100 | 50、100 |

| Density(g/cm3) | 1.6 | |||

| Base | Carbon fiber reinforced polymer with an epoxy resin matrix | |

| Shelf Life | Unlimited (no exposure to direct sunlight) | |

| Color | Black carbon fiber laminate | |

| Tensile Strength | Mean Value | 3100MPa |

| Design Value | 2600MPa | |

| Modulus Of Elasticity | Mean Value | 165,000MPa |

| Design Value | 160,000MPa | |

| Elongation at Break | 1.7% | |

| Thickness | 1.2mm, 1.4mm, 2.0mm, 3.0mm | |

| Temperature Resistance | >300° F(>150℃) | |

| Fiber Volumetric Content | >68% | |

| Density | 0.058 lbs./in 3 (1.6g/cm3) | |

Package

The length of the carbon fiber laminate is 100m, the width is divided into 50mm, 100mm; the thickness is divided into 1.2mm, 1.4mm, 2.0mm, 3.0mm. Roll into a ring and use a belt to bind. Other specifications can be customized.

Operation Process of CFRP Strip/Laminate/Plate Strengthening

Setting line according to design;

Polish the surface of concrete surface to remove painting of

surface, blow out that floating dust with compressed air;

Prepare ingredients: agitate component A and B evenly in

packaging bucket by weighting in accordance with the weight

ratio A:B=2:1;

Applying adhesive: paste the above mixed glue compounds onto

the surface of carbon fiber strip evenly, please avoid bubbles;

Installation: paste the carbon fiber strip onto the concrete surface

and fixed with steel strip;

Remove excessive glue compounds around, and fix with steel

framework;

Maintenance: conservation time should be no less than 24 hours

at room temperature.