Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

Before FRP composite strengthening, please reconfirm whether the concrete repair surface is clean and no foreign matter. After confirmation, make sure that the bottom glue is evenly applied on the top and bottom glue, otherwise there will be bubbles in the later carbon fiber composite materials.

Experience summary: key points of fiber reinforced polymer(FRP) composite strengthening

Before FRP composite strengthening, please reconfirm whether the concrete repair surface is clean and no foreign matter. After confirmation, make sure that the bottom glue is evenly applied on the top and bottom glue, otherwise there will be bubbles in the later carbon fiber composite materials.

In order to prevent carbon fiber composite materials damaged, steel ruler and wallpaper knife are used to cut off carbon fiber composite materials according to the specified size in the process of transportation, storage, cutting and pasting of carbon fiber material, and the length of each segment is generally not more than 6 m. In order to prevent material from being damaged during storage, the number of materials should be cut according to the amount of the day. The carbon fiber longitudinal joint must be lapped over 20cm. The area should be coated with resin, and the transverse carbon fibers need not be lapped.

Carbon fiber glue AB component should be accurately weighed according to the prescribed proportion, into the container, stirred evenly with a stirrer. A harmonic quantity should be used within the available time.

When carbon fiber fabric is pasted, do not have any air between carbon fiber fabric and carbon fiber adhesive. Special tools can be used along the fiber direction and rolling many times, so that resin immersion in carbon fiber fabric.

After curing and pasting the FRP composite material, it should be naturally cured for 1-2 hours to reach the initial curing stage. It should be guaranteed that the curing period is free from external interference and collision.

If reinforced components need fire protection, they can be painted with fireproof coating after curing. Painting shall be carried out at the initial curing stage of the resin and shall comply with the relevant standards and construction requirements for the coatings used.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Part A (Epoxy): 20kg

Part B(Hardener):10kg

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

Bar

Part A (Epoxy): 15kg

Part B (Hardener): 5kg

Mix Ratio: Part A: Part B=3:1

Barrel A Size: 30*30*37cm

Barre

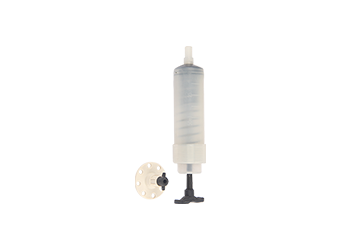

Volum: 75ML

Epoxy injctor is the tool to inject the epoxy into the crack.