Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

Wrapping carbon fiber reinforced polymer(FRP) fabric can improve the shear capacity of concrete columns, change their failure modes and improve their ductility.

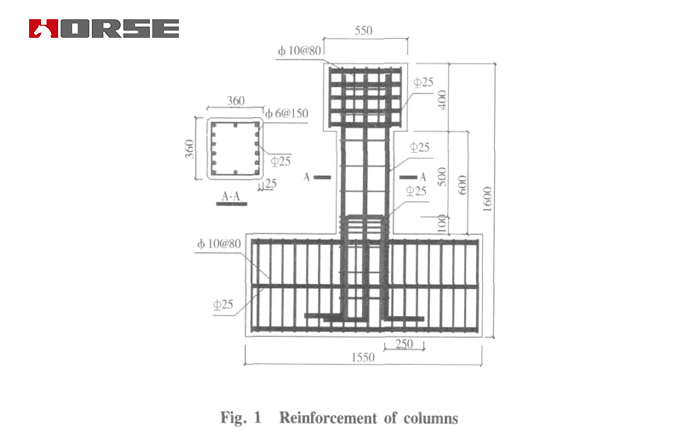

The common failure modes of reinforced concrete columns under transverse loads are shear failure, bending failure and ductile shear failure (also known as bending-shear failure in China). Under earthquake action, the reinforced concrete columns must have certain failure ductility while ensuring the bearing capacity. When bending failure occurs, it has necessary ductility, and its ductility is easy to estimate. When shear failure or ductile shear failure occurs, its ductility is usually insufficient, and its ductility is difficult to estimate. Therefore, it is necessary to prevent brittle failure modes such as shear failure of reinforced concrete columns, and reinforcement methods of reinforced concrete columns with insufficient shear capacity or ductility, such as enlarged section reinforcement, steel casing reinforcement and wrapping carbon fiber fabric reinforcement, etc. Previous studies have shown that transverse wrapping FRP fabric can improve the shear capacity of concrete columns, change their failure modes and improve their ductility.

1. The failure mode of reinforced concrete rectangular columns strengthened with FRP fabric can be changed from brittle shear failure to ductile shear failure and then to bending failure with the increase of FRP layers. Reflected in the skeleton curve, after the yield of the specimen, with the increase of FRP fabric reinforcement, the specimen has better sustained bearing capacity. After peak load, a section of horizontal platform appears. The larger the reinforcement, the longer the length of the platform, the better the deformation capacity of the specimen.

2.With the different amount of reinforcement, FRP fabric strengthened RC rectangular columns may occur brittle shear failure, ductile shear failure and bending failure. When ductile shear failure occurs, the longitudinal reinforcement can yield, but the bending capacity decreases rapidly after peak load, and the failure mode of shear plane FRP fabric oblique fracture occurs. When the specimens are subjected to bending failure, the bending capacity of the specimens can be maintained stable under large deformation conditions, and the failure mode caused by the loss of restraint due to the local fracture of FRP fabric at the corner root occurs.

3.The failure mode of reinforced concrete rectangular columns strengthened with FRP fabric can be predicted by the intersection relationship between the bending capacity skeleton curve and the shear capacity skeleton curve. The process is as follows. Through test or numerical analysis, the skeleton curve of bending capacity of FRP fabric reinforced concrete rectangular column is obtained. Based on the shear bearing capacity skeleton curve of ordinary concrete columns, the shear bearing capacity skeleton curve of reinforced concrete columns strengthened with FRP fabric is obtained by superimposing the shear bearing capacity subentry of FRP fabric. According to the intersection of the bending capacity skeleton curve and the shear capacity skeleton curve, different failure modes are determined. If the intersection of the two curves is located in the degenerate section of the theoretical shear capacity skeleton curve, ductile shear failure will occur. If the two curves can not intersect, ductile bending failure will occur.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Weight: 200g/sqm

Thickness: 0.111mm

Density: 1.8g/cm³

Packing: 100 meters/roll

Width:100mm, 200mm, 300mm, 500mm or to be custo

Part A: Modified Epoxy (20kg)

Part B: Hardner(10kg)

Mix Ratio: A:B=2:1

Consumption Ratio: 0.2-0.3kg/sqm

Barrel A Size: 30*30