• Double component bidphenol-A modified epoxy resin based adhesive, non-hydrophilic, high bonding strength, water proof, anti-cprrpsion, environmental-friendly;

• Application in wide temperature scope;

• Excellent acid/alkali resistance and aging resistance, low moisture sensitivity.

Characteristics of Epoxy Resin• Double component bidphenol-A modified epoxy resin based adhesive, non-hydrophilic, high bonding strength, water proof, anti-cprrpsion, environmental-friendly; • Application in wide temperature scope; • Excellent acid/alkali resistance and aging resistance, low moisture sensitivity. |

|

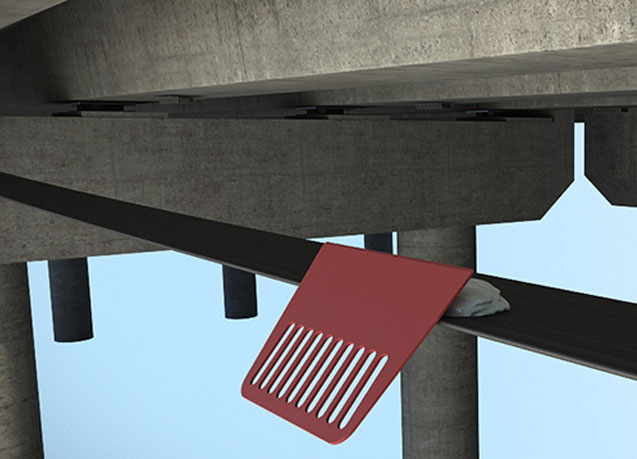

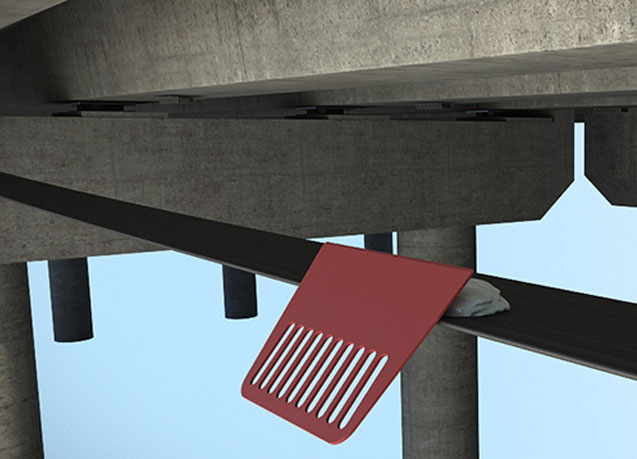

• Use together with HM carbon fiber plate to fix on concrete surface

• Used for structure reinforcement with HM pre-stress carbon fiber laminate system

|

Application Range• Use together with HM carbon fiber plate to fix on concrete surface • Used for structure reinforcement with HM pre-stress carbon fiber laminate system |

• The carbon fiber adhesive should store in a cool and dry place,storage period is 12 months. If storage period exceed 12 months, the product should be tested, if the physical and mechanical properties meet the standard requirements,you can still continue to use it.

• This product is non-toxic, belong to non-dangerous goods, transport as a goods, transport as a general chemical building materials

Transportation and Storage• The carbon fiber adhesive should store in a cool and dry place,storage period is 12 months. If storage period exceed 12 months, the product should be tested, if the physical and mechanical properties meet the standard requirements,you can still continue to use it. • This product is non-toxic, belong to non-dangerous goods, transport as a goods, transport as a general chemical building materials |

|

• Mix proper quantity, use up in the applicable period.

• If there is any left, the lids of A B should be covered. Do not expose it in the air.

• Construction workers should take certain protective measures.

• The construction environment should be kept ventilated during construction.

• Avoid direct sunlight and high temperature.

|

Attention Points• Mix proper quantity, use up in the applicable period. • If there is any left, the lids of A B should be covered. Do not expose it in the air. • Construction workers should take certain protective measures. • The construction environment should be kept ventilated during construction. • Avoid direct sunlight and high temperature. |

| Technical Parameters | |

| Appearance | Part A Grey Part B White |

| Density after curing | 1.6 g/cm3 |

| Mixture Ratio (By weight) | 2:1 |

| Operation time | 30 min |

| Shelf life | 12 months |

| Mechanical Properties | ||

| item | index | |

| Colloidal Performance | Tensile Strength(MPa) | ≥30 |

| Tensile Elastic Modulus(MPa) | ≥3500 | |

| Elongation(%) | ≥1.3 | |

| Bending Strength(MPa) | ≥45 | |

| Compressive Strength(MPa) | ≥65 | |

| Bonding Properties | Steel- Steel Shear Strength(MPa) | ≥15 |

| Steel- Steel Shear Strength(MPa) | ≥16 | |

| Steel- Steel Bonding Strength(MPa) | ≥33 | |

| Bonding Strength with Concrete(MPa) | ≥2.5 | |

| Nonvolatile Content(Solid Content)(%) | ≥99 | |

HM-120CP Carbon Plate Adhesive Install

1.Setting out according to designing;

2.Polish the surface of concrete surface to remove painting of the surface, blow out the floating dust with compressed air;

3.Prepace ingredients: agitate component A and B evenly in packaging bucket by weighting in accordance with the weight ratio A:B=2:1;

4.Installing: Past the above mixed glue compounds onto the surface of carbon fiber plate evenly, please avoid bubbles;

5.Anchorage: paste the carbon fiber plate onto the concrete surface and fixed with steel srtip, remove excessive glue conpounds around, and fix With Steel framework;

6.Maintenace: conservation time should be no less than 24 hours at room temperature.