Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

The crack width and the crack spacing of the beams strengthened with carbon fiber fabric are significantly reduced compared with those of the unreinforced beams.

Carbon fiber fabric has been widely used to reinforce concrete structures. It is widely used to paste carbon fiber fabric on the bottom of concrete beams to improve their flexural capacity, reduce their crack width and improve their normal performance.

At present, there are many experimental and computational studies on the flexural capacity of reinforced concrete beams, but few on the reduction of crack width and its calculation. According to the causes and locations of cracks, they can be classified into the following categories.

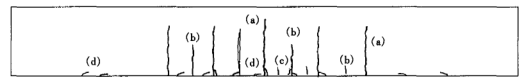

1) Principal cracks caused by bending stress. After the cracking load, the first cracks (a) as shown in Fig. 1 are produced. With the increase of load, a new crack (b) will occur between cracks (a), which will rise higher with the further increase of load. The distribution of these cracks depends on the comprehensive bond between steel bar and carbon fiber fabric and concrete. This paper is generally called the main crack.

2) secondary cracks near reinforcing bars. Because the local bond stress between carbon fiber fabric and concrete is large, the tensile stress between the main cracks reaches the tensile strength of concrete, resulting in short secondary cracks (C). Because the influence of local bond stress between carbon fiber fabric and concrete is small, the development height of this kind of secondary crack is also small.

3) secondary cracks near main fractures. Because the opening of the main crack at the bottom of the beam is limited by the carbon fiber fabric, when the carbon fiber fabric is subjected to a large force, the interface between the carbon fiber fabric and the concrete produces local stripping cracks (d). Such cracks are generally short oblique cracks, some of which intersect with the main cracks, resulting in the loosening of the concrete. When the amount of reinforcement is large, the crack tends to be horizontal.

A large number of experimental studies show that the crack width and the crack spacing of the beams strengthened with carbon fiber fabric are significantly reduced compared with those of the unreinforced beams.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Thickness:1.2mm, 1.4mm, 2.0mm, 3.0mm

Density: 1.6g/cm³

Packing: 100 meters/roll

Width: 50mm, 100mm or to be custo

Part A (Epoxy): 20kg

Part B (Hardener): 1kg

Mix Ratio: Part A: Part B=20:1

Barrel A Size: 30*30*37cm

Barre

Part A: Modified Epoxy (20kg)

Part B: Hardner(10kg)

Mix Ratio: A:B=2:1

Consumption Ratio: 0.2-0.3kg/sqm

Barrel A Size: 30*30