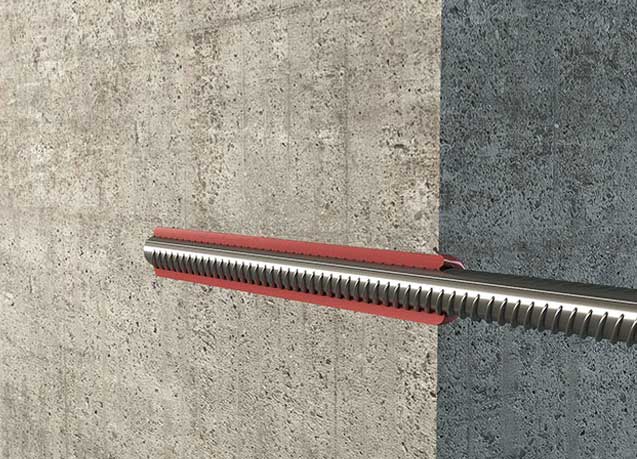

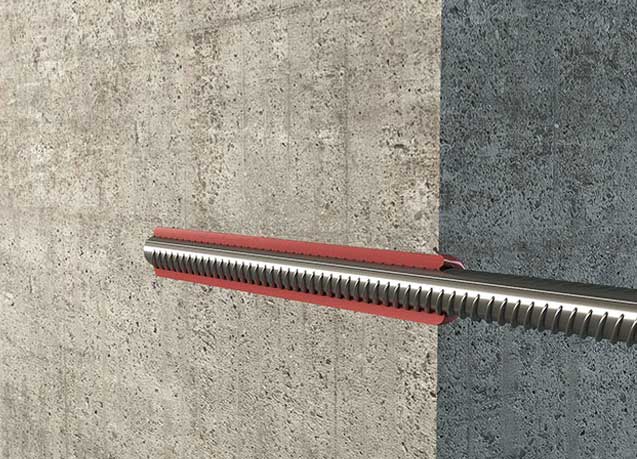

• Modified epoxy resin, high strength, corrosion resistance, acid-alkali resistance, aging resistance;

• Curing at room temperature, easy to install;

• Wide adhesive range, such as concrete, stone materials and metals;

• No expansion or contraction after curing, no destroy to substrate;

• Environment friendly, non-toxic, do not contain volatile solvents.

Key Characteristics• Modified epoxy resin, high strength, corrosion resistance, acid-alkali resistance, aging resistance; • Curing at room temperature, easy to install; • Wide adhesive range, such as concrete, stone materials and metals; • No expansion or contraction after curing, no destroy to substrate; • Environment friendly, non-toxic, do not contain volatile solvents. |

|

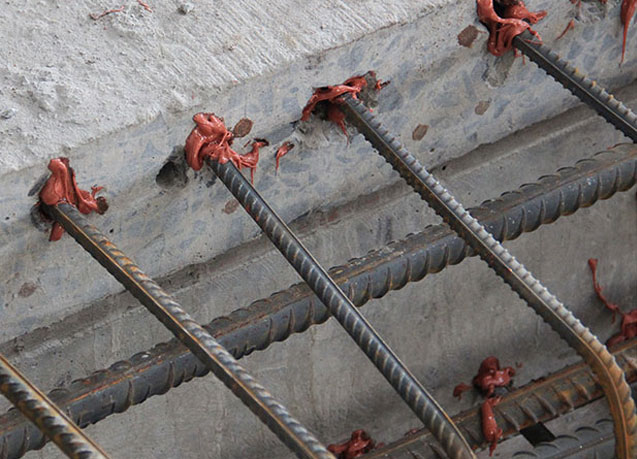

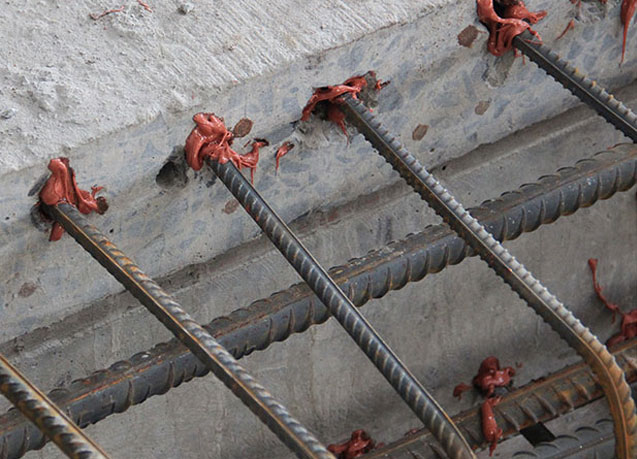

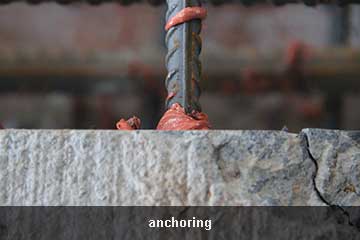

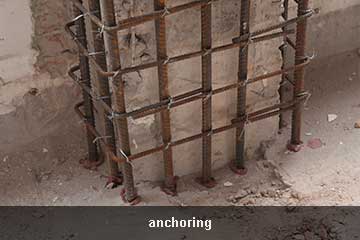

• The steel bar planting and the anchor bolt anchoring of many kinds of building structures, the reinforcement of engineering buildings;

• The basic anchoring of many equipments, the anchoring and supporting of mine tunnel top and wall, the anchoring of railways and rails;

• The insulation anchoring of rails, the installation anchoring of curtain walls, chemical engineering equipments, pipelines, advertisement boards and so on;

• The anchoring of water conservancy facilities, docks, public roads, bridges and other projects.

|

Application Range• The steel bar planting and the anchor bolt anchoring of many kinds of building structures, the reinforcement of engineering buildings; • The basic anchoring of many equipments, the anchoring and supporting of mine tunnel top and wall, the anchoring of railways and rails; • The insulation anchoring of rails, the installation anchoring of curtain walls, chemical engineering equipments, pipelines, advertisement boards and so on; • The anchoring of water conservancy facilities, docks, public roads, bridges and other projects. |

• The carbon fiber adhesive should store in a cool and dry place,storage period is 12 months. If storage period exceed 12 months, the product should be tested, if the physical and mechanical properties meet the standard requirements,you can still continue to use it.

• This product is non-toxic, belong to non-dangerous goods, transport as a goods, transport as a general chemical building materials

Transportation and Storage• The carbon fiber adhesive should store in a cool and dry place,storage period is 12 months. If storage period exceed 12 months, the product should be tested, if the physical and mechanical properties meet the standard requirements,you can still continue to use it. • This product is non-toxic, belong to non-dangerous goods, transport as a goods, transport as a general chemical building materials |

|

• Mix proper quantity, use up in the applicable period.

• If there is any left, the lids of A B should be covered. Do not expose it in the air.

• Construction workers should take certain protective measures.

• The construction environment should be kept ventilated during construction.

• Avoid direct sunlight and high temperature.

|

Attention Points• Mix proper quantity, use up in the applicable period. • If there is any left, the lids of A B should be covered. Do not expose it in the air. • Construction workers should take certain protective measures. • The construction environment should be kept ventilated during construction. • Avoid direct sunlight and high temperature. |

| HM-500 Structure Anchor Adhesive Performance Parameters | |

| Appearance | A(main agent): red or white paste |

| B(curing agent): brown paste | |

| Viscosity of mixture | ≥22Pa·s |

| Density of curing material | 1.60±0.10g/cm3 |

| Mixture ratio(weight ratio) | 2:1 |

| Storage period | twelve months |

| HM-500 Structure Anchor Adhesive Operable time and curing time | |||||

| Ambient temperature(℃) | -5 | 0 | 10 | 20 | ≥30 |

| Operable time(min) | 60 | 45 | 30 | 25 | 20 |

| Curing time(h) | 72 | 48 | 24 | 12 | 6 |

| HM-500 Structure Anchor Adhesive Performance indexes | ||||

| item | index | item | index | |

| Colloidal

performance |

Splitting tensile strength(MPa) | ≥8.5 | Thixotropic index | ≥4.0 |

| Bending Strength(MPa) | ≥50 | Sagging mobility | ≤2.0mm | |

| Compressive strength(MPa) | ≥60 | Distortion temperature | ≥65℃ | |

| Adhesion

performance |

Steel-steel(steel sleeve)tensile anti-shear strength(MPa) | ≥10 | ||

| Under the constraint drawing condition,

ribbed steel bars and C30, φ25, L=150mm(MPa) |

≥11 | |||

| Adhesion strength of concrete C60, φ25, L=125mm(MPa) | ≥17 | |||

| Steel-steel T impact stripping length | ≤25mm | |||

| Non-volatile matter content(solid content)(%) | ≥99 | |||

| Long-term

performance |

Wet and heat ageing

resistance ability |

Compared with the short-term results at room temperature,

the decrease rate of shear strength:≤12% |

||

| Heat aging resistance | Compared with the short-term results at same temperature 10min,

the decrease rate of shear strength: ≤5% |

|||

| Freezing and thawing

resistance ability |

Compared with room temperature, short-term results,

the shear strength decrease rate is not greater than 5% |

|||

| Fatigue stress

resistance ability |

After2×106 times continuous sine wave fatigue loads,

specimen does not destroy |

|||

| Resistance to stress

for a long time |

Steel – steel tensile shear specimens does not destroy,

and creep deformation value is less than 0.4 mm |

|||

| Resistance to

corrosion medium |

Resistance to salt

fog effect |

Compared with the control group, the strength decrease rate: ≤5%,

and shall not have cracks or come unglued |

||

| Alkaline medium

resistance ability |

Compared with the control group, the strength does not decrease,

and as the concrete damage, and shall not have cracks or come unglued |

|||

| Acid medium

resistance ability |

Concrete damage, and shall not have cracks or degumming | |||