• High strength

• Wet resistance

• Anti-aging

• Convenience

• Good thixotropy

• Safe and Non-toxic

• Seismic resistance

Manufacturer of Anchoring Adhesive• High strength |

|

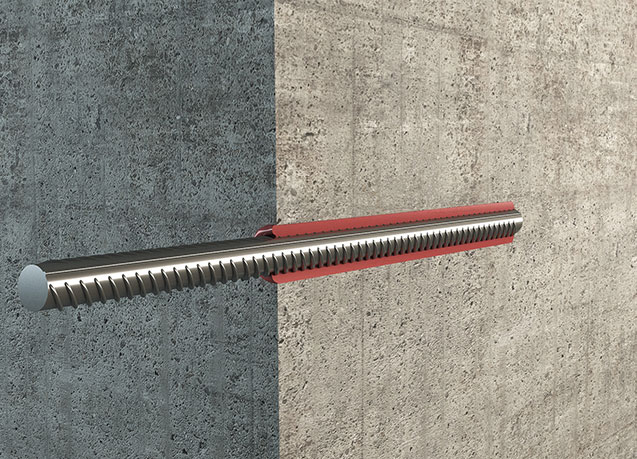

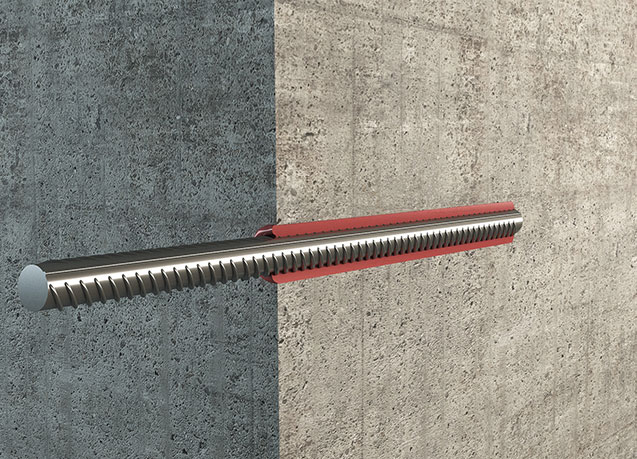

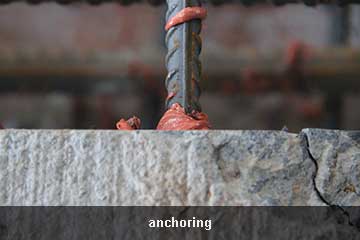

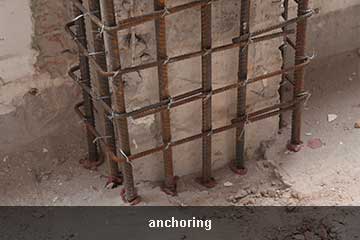

• Structural connections with post-installed rebar (e.g. extension/connection to walls, slabs, stairs, columns, foundations, etc.)

• Structural renovation of buildings, bridges and other civil structures, retrofitting and re-strengthening of concrete members possible

• Anchoring structural steel connections (e.g. steel columns, beams, etc.)

|

Application Range• Structural connections with post-installed rebar (e.g. extension/connection to walls, slabs, stairs, columns, foundations, etc.) • Structural renovation of buildings, bridges and other civil structures, retrofitting and re-strengthening of concrete members possible • Anchoring structural steel connections (e.g. steel columns, beams, etc.) |

• Viscosity of Mixture:18-22Pa•S

• Splitting tensile strength ≥8.5MPa

• Bending strength ≥50MPa

• Compressive strength ≥60MPa

• Thixotopy index ≥4.0

• Distortion temperature ≥65℃

• Steel-steel tensile shear strength ≥16MPa

• C30,φ25, L=150mm condition tensile strength ≥11MPa

• C30,φ25, L=125mm condition bonding strength ≥17MPa

• Steel-steel T impact stripping length ≤25mm

Technical Data Sheet• Viscosity of Mixture:18-22Pa•S |

|

• 100% Pass the pull-out testing

No matter test on site or sampling testing are 100% passing the test.

• Special formulas

Special formulas, making the substrates are together with the adhesive to be a new complete structure.

• Strong extensible

Epoxy have elastic reaction globule, make the chemical anchoring epoxy not only with strength, viscosity but also toughness.

• Excellent tension properties

Keep the superior properties and work-ability even under the hole smooth, damp or hot weather.

|

Advantages of Injectable Epoxy• 100% Pass the pull-out testing • Special formulas • Strong extensible • Excellent tension properties |

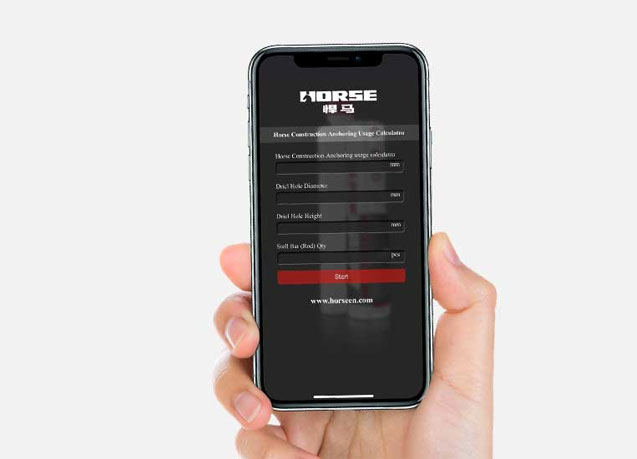

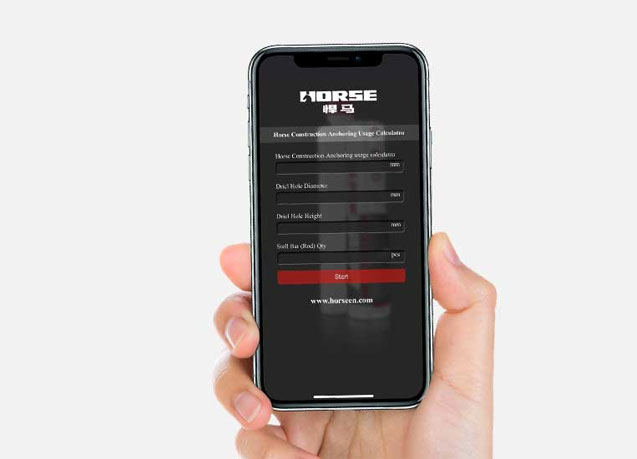

Quickly and accurately calculate the usage of HM-500 (chemical anchoring epoxy) to save your time.

http://www.horseen.com/calculator/calculator.html

Patent Anchoring Adhesive CalculatorQuickly and accurately calculate the usage of HM-500 (chemical anchoring epoxy) to save your time. http://www.horseen.com/calculator/calculator.html |

|

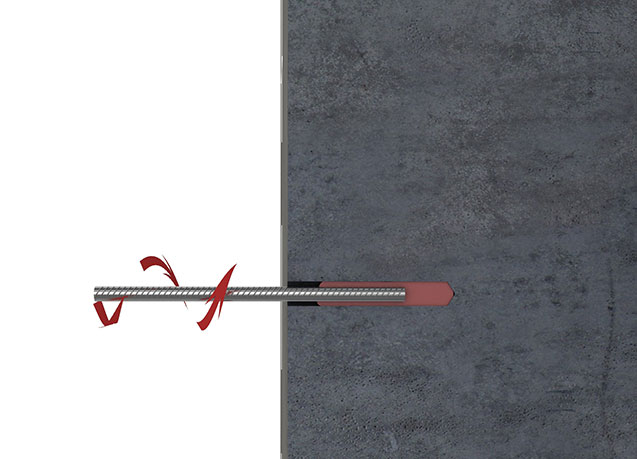

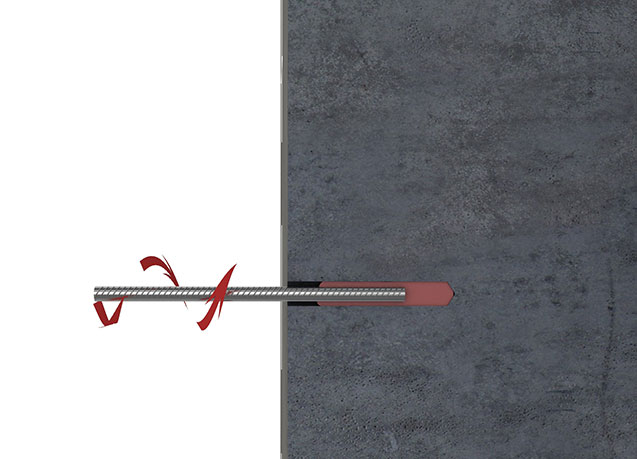

• Drill hole

• Clean hole

• Brush hole

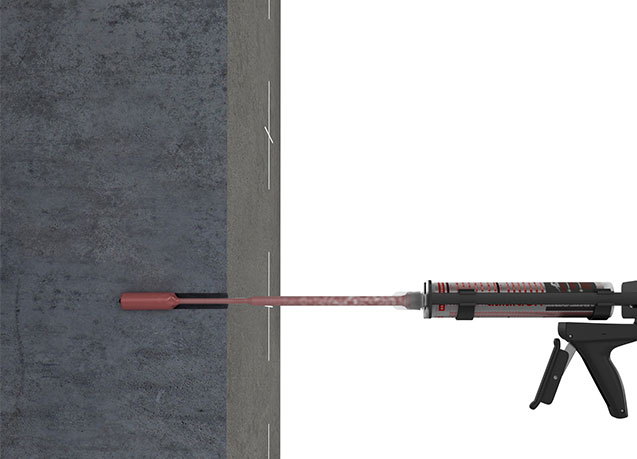

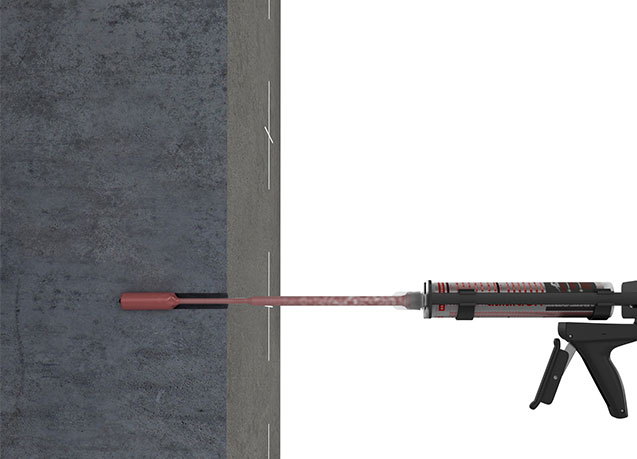

• Inject adhesive

• Plant rebar

• Curing

|

How to Use Anchoring Adhesive• Drill hole |

HM-500 Injactable Anchoring Adhesive

![]() HM500 Epoxy Anchor Adhesive Technical Data Sheet.pdf

HM500 Epoxy Anchor Adhesive Technical Data Sheet.pdf

| HM-500 concrete injectable anchoring adhesive performance parameters | |

| Appearance | A(main agent): white paste |

| B(curing agent): red or black paste | |

| Viscosity of mixture | 18~22 Pa·s |

| Density of curing material | 1.50±0.10g/cm3 |

| Mixture ratio (volume ratio) | 3:1 |

| Storage period | 12 months |

| Packageing | 390ml |

| Operable time and curing time | |||||

| Ambient temperature(℃) | -5 | 0 | 10 | 20 | ≥30 |

| Operable time(℃) | 60 | 45 | 30 | 25 | 20 |

| Curing time(h) | 72 | 48 | 24 | 12 | 6 |

| HM-500 concrete injectable anchoring adhesive performance indexes | ||||

| item | index | item | index | |

| Colloidal performance | Splitting tensile strength(MPa) | ≥8.5 | Thixotropic index | ≥4.0 |

| Bending strength(MPa) | ≥50 | Sagging mobility | ≤2.0mm | |

| Compressive strength(MPa) | ≥60 | Distortion temperature | ≥65℃ | |

| Adhesion performance | Steel-steel (steel sleeve) tensile anti-shear strength(MPa) | ≥10 | ||

| Under the constraint drawing condition, ribbed steel bars and C30, φ25, L=150mm(MPa) | ≥11 | |||

| Adhesion strength of concrete C60, φ25, L=125mm(MPa) | ≥17 | |||

| Steel-steel T impact stripping length | ≤25mm | |||

| Non-volatile matter content(solid content)(%) | ≥99 | |||

| Long-term performance | Wet and heat ageing

resistance ability |

Compared with the short-term results at room temperature,

the decrease rate of shear strength: ≤12% |

||

| Heat aging resistance | Compared with the short-term results at same temperature 10min,

the decrease rate of shear strength: ≤5% |

|||

| Freezing and thawing

resistance ability |

Compared with room temperature, short-term results,

the shear strength decrease rate is not greater than 5% |

|||

| Fatigue stress

resistance ability |

After2×106 times continuous sine wave fatigue loads,

specimen does not destroy |

|||

| Resistance to stress

for a long time |

Steel – steel tensile shear specimens does not destroy,

and creep deformation value is less than 0.4 mm |

|||

| Resistance to corrosion medium | Resistance to salt

fog effect |

Compared with the control group, the strength decrease rate: ≤5%,

and shall not have cracks or come unglued |

||

| Alkaline medium

resistance ability |

Compared with the control group, the strength does not decrease,

and as the concrete damage, and shall not have cracks or come unglued |

|||

| Acid medium

resistance ability |

Concrete damage, and shall not have cracks or degumming | |||

The reference table of HM-500 anchor adhesive planting and anchoring binding force

*The anchoring adhesion when planting steel bars

| The steel

bar diameter φ(mm) |

The diameter of

drilled hole D(mm) |

The yield

characteristic value of steel bars(kN) |

The anchoring adhesion(characteristic value)RK(kN) | The steel bar

yield planting depth lb(mm) |

||||||||||

| 10 | 13 | 26.3 | 26.1 | 26.3 | 26.3 | 26.3 | 105 | |||||||

| 12 | 16 | 37.9 | 36.2 | 37.9 | 37.9 | 37.9 | 125 | |||||||

| 14 | 18 | 51.6 | 45.2 | 49.8 | 51.6 | 51.6 | 51.6 | 150 | ||||||

| 16 | 20 | 67.4 | 60.3 | 67.4 | 67.4 | 67.4 | 67.4 | 175 | ||||||

| 18 | 22 | 85.2 | 74.6 | 82.9 | 85.2 | 85.2 | 85.2 | 200 | ||||||

| 20 | 25 | 105.2 | 94.2 | 100.5 | 105.2 | 105.2 | 105.2 | 220 | ||||||

| The steel bar buried depth(mm) | 80 | 90 | 100 | 110 | 120 | 135 | 150 | 160 | 180 | 200 | 220 | |||

| The steel

bar diameter φ(mm) |

The diameter of

drilled hole D(mm) |

The yield

characteristic value of steel bars(kN) |

The anchoring adhesion(characteristic value)RK(kN) | The steel bar

yield planting depth lb(mm) |

||||||||||

| 22 | 28 | 127.3 | 112.5 | 126.6 | 127.3 | 127.3 | 127.3 | 240 | ||||||

| 25 | 32 | 164.4 | 144.8 | 160.8 | 164.4 | 164.4 | 164.4 | 164.4 | 270 | |||||

| 28 | 35 | 206.3 | 175.9 | 193.4 | 206.3 | 206.3 | 206.3 | 206.3 | 305 | |||||

| 32 | 40 | 269.4 | 241.3 | 251.3 | 269.4 | 269.4 | 269.4 | 350 | ||||||

| 40 | 50 | 421.0 | 339.3 | 383.3 | 421.0 | 421.0 | 421.0 | 440 | ||||||

| The steel bar buried depth(mm) | 160 | 180 | 200 | 220 | 240 | 250 | 270 | 305 | 350 | 400 | 440 | |||

Notes:1.Contcrete strength is C30,II grade steel yield strength is 335 N/mm2.

2.The diameter of drilling holes in the table is the best recommended value,the nearest bit can be selected according to the situation.

3.The yield buried depth value of the steel bars should consider safety factors,and select the design values.

*The anchoring adhesion when planting steel bars

| The steel

bar diameter φ(mm) |

The diameter of

drilled hole D(mm) |

The yield

characteristic value of steel bars(kN) |

The anchoring adhesion(characteristic value)Rd(kN) | The steel bar

yield planting depth lb(mm) |

||||||||||

| 10 | 13 | 22.9 | 17.4 | 19.6 | 21.8 | 22.9 | 105 | |||||||

| 12 | 16 | 33.0 | 24.1 | 26.8 | 29.5 | 33.0 | 125 | |||||||

| 14 | 18 | 44.8 | 30.1 | 33.2 | 36.2 | 40.7 | 44.8 | 150 | ||||||

| 16 | 20 | 58.5 | 40.2 | 45.1 | 50.1 | 53.5 | 58.5 | 175 | ||||||

| 18 | 22 | 74.1 | 49.7 | 55.3 | 59.0 | 66.4 | 74.1 | 200 | ||||||

| 20 | 25 | 91.5 | 62.8 | 67.0 | 75.3 | 83.7 | 91.5 | 220 | ||||||

| The steel bar buried depth(mm) | 80 | 90 | 100 | 110 | 120 | 135 | 150 | 160 | 180 | 200 | 220 | |||

| The steel

bar diameter φ(mm) |

The diameter of

drilled hole D(mm) |

The yield

characteristic value of steel bars(kN) |

The anchoring adhesion(characteristic value)Rd(kN) | The steel bar

yield planting depth lb(mm) |

||||||||||

| 22 | 28 | 110.7 | 75.0 | 84.4 | 93.8 | 103.2 | 110.7 | 240 | ||||||

| 25 | 32 | 143.0 | 96.5 | 107.2 | 118.0 | 128.7 | 134.0 | 143.0 | 270 | |||||

| 28 | 35 | 179.3 | 117.2 | 128.9 | 140.6 | 146.5 | 158.3 | 179.3 | 305 | |||||

| 32 | 40 | 234.2 | 160.8 | 167.3 | 181.0 | 204.4 | 234.2 | 350 | ||||||

| 40 | 50 | 365.9 | 226.2 | 255.5 | 293.1 | 334.9 | 365.9 | 440 | ||||||

| The steel bar buried depth(mm) | 160 | 180 | 200 | 220 | 240 | 250 | 270 | 305 | 350 | 400 | 440 | |||

Notes:Concrete strength is C30,the designed strength of grade II steel bar is 310 N/mm2.

The designed safety coefficient of steel bar ys=1.15,the designed safety coefficient of concrete yc=1.5.

| The anchoring adhesion when planting steel bars | ||||||

| The screw

diameter |

The diameter

of drilled hole(mm) |

The buried

depth(mm) |

Characteristic value | Designed value | ||

| Tensile resistance(kN) | Shearing resistance(kN) | Tensile resistance(kN) | Shearing resistance(kN) | |||

| M8 | 10 | 80 | 15.8 | 8.5 | 7.5 | 5 |

| M10 | 12 | 90 | 22.9 | 13.7 | 12.5 | 8 |

| M12 | 14 | 110 | 46.9 | 20.0 | 19 | 11.8 |

| M16 | 18 | 125 | 65.6 | 37.8 | 29 | 22.2 |

| M20 | 25 | 170 | 85.3 | 59.0 | 42.5 | 34.7 |

| M24 | 28 | 210 | 170 | 85.0 | 59.7 | 50 |

| M30 | 35 | 280 | 206.0 | 135.9 | 89 | 79.4 |

The table of using gule quantities of HM-500 epoxy anchor adhesive

| the steel

bar diameter |

pore

size |

pore

depth |

the injecting

glue volume |

theoretic

number |

note |

| mm | mm | mm | ml(2/3v) | piece | |

| 8 | 12 | 80 | 6.03 | 64.67 | 10d |

| 8 | 12 | 120 | 9.04 | 43.14 | 15d |

| 8 | 12 | 160 | 12.06 | 32.33 | 20d |

| 10 | 14 | 100 | 10.26 | 38.01 | 10d |

| 10 | 14 | 150 | 15.08 | 25.86 | 15d |

| 10 | 14 | 200 | 20.52 | 19.01 | 20d |

| 12 | 16 | 120 | 16.09 | 24.23 | 10d |

| 12 | 16 | 180 | 24.12 | 16.16 | 15d |

| 12 | 16 | 240 | 32.18 | 12.11 | 20d |

| 14 | 18 | 140 | 23.73 | 16.43 | 10d |

| 14 | 18 | 210 | 35.61 | 10.95 | 15d |

| 14 | 18 | 280 | 47.46 | 8321 | 20d |

| 16 | 22 | 160 | 40.52 | 9.62 | 10d |

| 16 | 22 | 240 | 60.79 | 6.41 | 15d |

| 16 | 22 | 320 | 81.04 | 4.81 | 20d |

| 18 | 25 | 180 | 58.87 | 6.62 | 10d |

| 18 | 25 | 270 | 88.31 | 4.41 | 15d |

| 18 | 25 | 360 | 117.74 | 3.31 | 20d |

| 20 | 28 | 200 | 82.06 | 4.75 | 10d |

| 20 | 28 | 300 | 123.09 | 3.16 | 15d |

| 20 | 28 | 400 | 164.12 | 2.37 | 20d |

| 22 | 30 | 220 | 103.62 | 3.76 | 10d |

| 22 | 30 | 330 | 155.43 | 2.5 | 15d |

| 22 | 30 | 440 | 207.24 | 1.88 | 20d |

| 25 | 32 | 250 | 133.97 | 2.91 | 10d |

| 25 | 32 | 375 | 200.96 | 1.94 | 15d |

| 25 | 32 | 500 | 267.95 | 1.45 | 20d |

HM-500 Structure Injectable Anchoring Adhesive

1.Drill hole to the diameter and depth required. The diameter must be in accordance with anchor size.

2.The drill hole must be cleaned with air blower, starting from the bottom of the hole.The drill hole mustbe thoroughly cleaned with steel brush. After brush, to use air blower to clean the drill hole again.

3.Inject the anchoring epoxy into the hole, starting from the bottom, while slowly drawing back the static mixer. In any case avoid entrapping air. For deep holes extension tubing can be used.

4.Insert the anchor with a rotary motion into the filled drill hole. Some adhesive must come out of the hole.

5.During the resin hardening time the anchor must not be moved or loaded.