• Very strong penetration, low viscosity.

• No volatile solvents, not shrinkage.

• High strength, high toughness and good impact resistance.

• Anti-aging, good acid and alkali resistance.

Manufacturer of Crack Injection• Very strong penetration, low viscosity. |

|

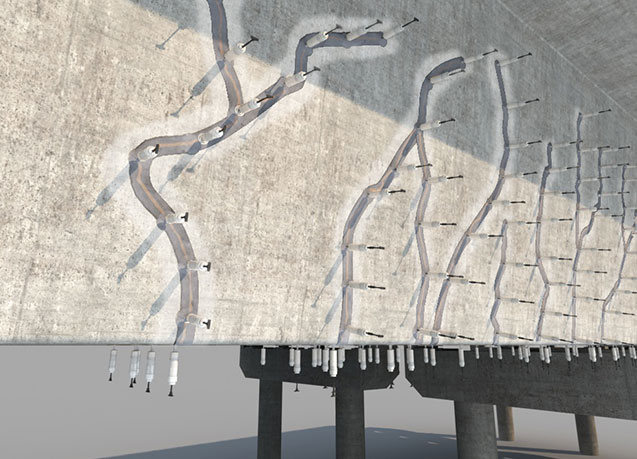

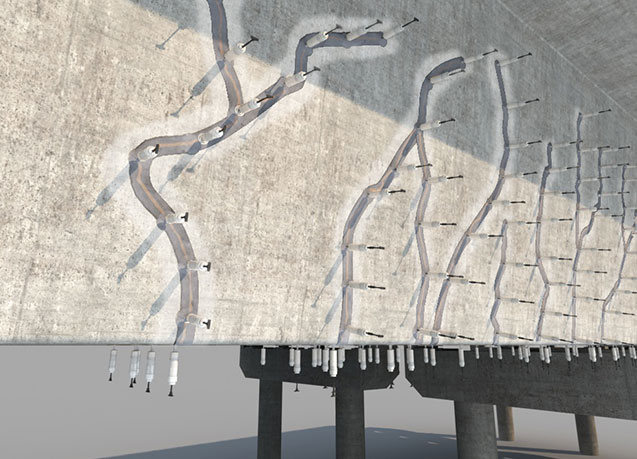

• Structural crack repairing, low pressure injection of cracks in structural concrete, masonry, wood, etc.

• The products are widely used in crack glue injection repair of concrete bridges, houses, water conservancy, roads and other projects, and reinforcing glue injection repair of concrete internal cellular, looseness and other defects, anti-corrosion construction of glass steel, structural surface coat.

• It is suitable for pouring bond of cracks generated by concrete members and brick members, to achieve repairing and reinforcing cracks.

|

Application Range• Structural crack repairing, low pressure injection of cracks in structural concrete, masonry, wood, etc. • The products are widely used in crack glue injection repair of concrete bridges, houses, water conservancy, roads and other projects, and reinforcing glue injection repair of concrete internal cellular, looseness and other defects, anti-corrosion construction of glass steel, structural surface coat. • It is suitable for pouring bond of cracks generated by concrete members and brick members, to achieve repairing and reinforcing cracks. |

• Crack inspection

• Crack treatments

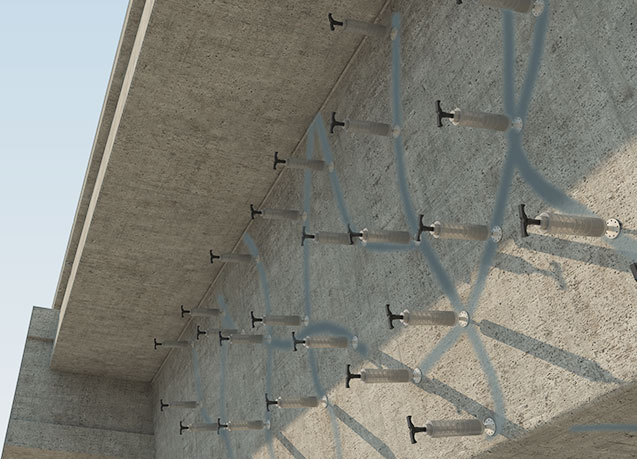

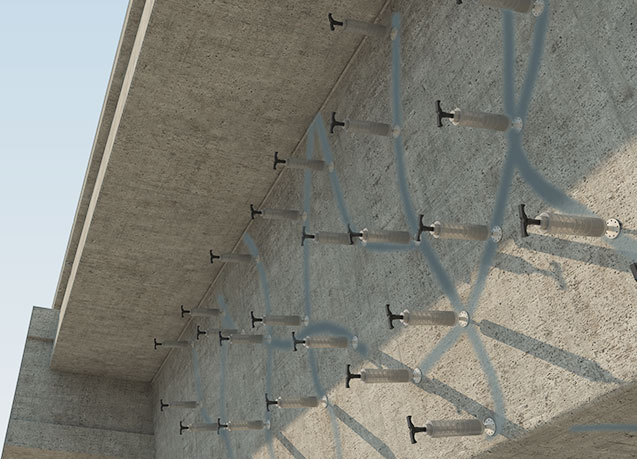

• Embed injection glue nozzle

• Seal crack

• Sealing check

• Prepare crack injection adhesive

• Inject the crack injection glue

• Curing

• Examination and test

How to Use• Crack inspection |

|

• Store in dry and clear store house of ambient temperature 5-25℃, shhuold not pile up in the open air or rain, not damage the package. A,B component shuold be kept separate to avoid mixing. From the date of production, effective storage perirod is 12 months.

• The crack injection adhesive belong to non-dangerous goods, transport as a genral chemical building materials, should not damage the package,exposure ,or rain, not tilt or invert in transportatio.

|

Transportation and Storage• Store in dry and clear store house of ambient temperature 5-25℃, shhuold not pile up in the open air or rain, not damage the package. A,B component shuold be kept separate to avoid mixing. From the date of production, effective storage perirod is 12 months. • The crack injection adhesive belong to non-dangerous goods, transport as a genral chemical building materials, should not damage the package,exposure ,or rain, not tilt or invert in transportatio. |

• Room temperature influence curing effect, high temperature promote curing rate, low temperature slow down curing rate.

• If accidentally swallowed or splashed into the eyes, please seek medical service at once.

Attention Points• Room temperature influence curing effect, high temperature promote curing rate, low temperature slow down curing rate. • If accidentally swallowed or splashed into the eyes, please seek medical service at once. |

|

| Crack Injection Adhesive Technical Parameters | |

| Colloid performance | |

| Package Part A (kgs) | 20 |

| Package Part B (kgs) | 7 |

| Ratio | 3:1 |

| Shelf Life | 18 months |

| Standard value of tensile strength(MPa) | ≥25 |

| Tensile elastic modulus(MPa) | ≥1.5×103 |

| Elongation(%) | ≥1.7 |

| Bending Strength(MPa) | ≥30, shall not been brittle failure |

| Compressive Strength(MPa) | ≥50 |

| Unconstrained linear shrinkage rate(%) | ≤0.3 |

| Adhesion capacity | |

| Steel-steel tensile shear strength(MPa) | ≥15 |

| Steel-steel docking tensile strength(MPa) | ≥20 |

| Steel -dry concrete bonding strength(MPa) | ≥2.5, concrete cohesion damage |

| Steel -wet concrete bonding strength(MPa) | ≥1.8, concrete cohesion damage |

HM-120L Crack Injection Adhesive operation process

• Crack inspection

• Crack treatments

• Embed injection glue nozzle

• Seal crack

• Sealing check

• Prepare crack injection adhesive

• Inject the crack injection glue

• Curing

• Examination and test