• improve the bearing capacity of bridge structure,has incomparable advantages in large-span beam slab of flexural reinforcement.

• significantly reduce deformation of the structure and improve the bearing capacity of structure,decrease the crack width and

deflection deformation,and is suitable for large span beam slab of flexural reinforcement.

• improve the stiffness of structure ,and make full use of the material performance ,save a lot of materials and engineering cost.

• improve the bearing capacity of bridge structure,has incomparable advantages in large-span beam slab of flexural reinforcement.

• significantly reduce deformation of the structure and improve the bearing capacity of structure,decrease the crack width and

deflection deformation,and is suitable for large span beam slab of flexural reinforcement.

• improve the stiffness of structure ,and make full use of the material performance ,save a lot of materials and engineering cost.

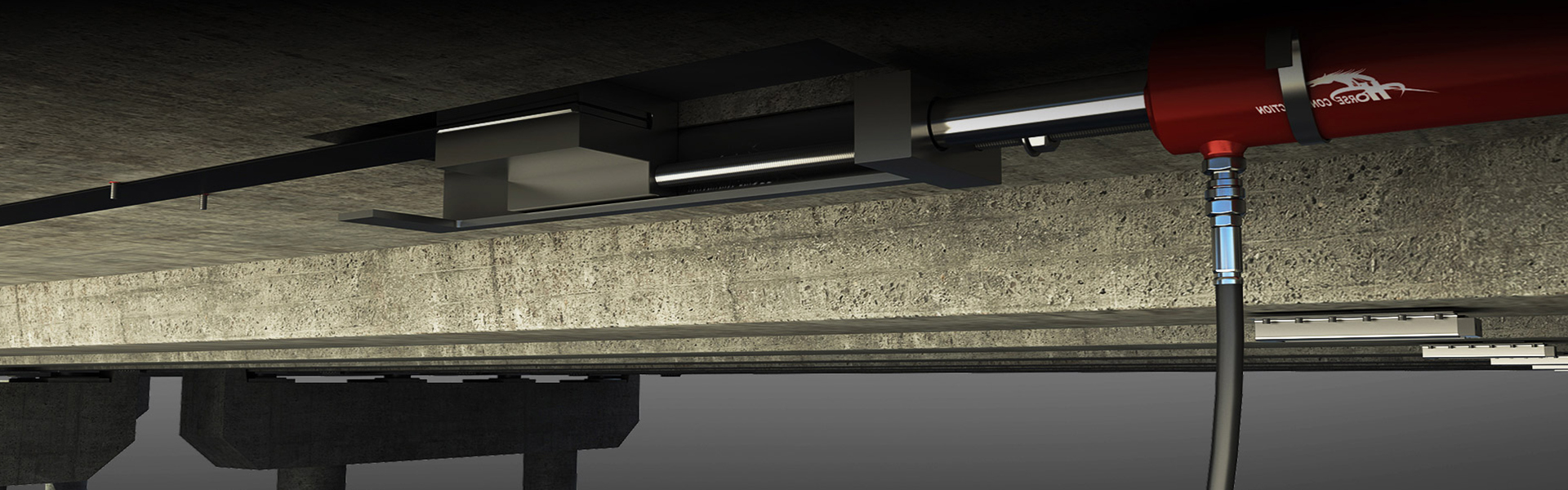

the increasing stress can remove or retard the stress hysteresis of the added structures, make the added structure work together with the original structure, to achieve a more efficient result

the increasing stress can remove or retard the stress hysteresis of the added structures, make the added structure work together with the original structure, to achieve a more efficient result

the hogging moment from prestess can offset some initial load influences, increase the load in working term, make the existing crack reducing or even closed completely, meanwhile limited the new cracks appearing.

the hogging moment from prestess can offset some initial load influences, increase the load in working term, make the existing crack reducing or even closed completely, meanwhile limited the new cracks appearing.

through the high pressure of the concrete and high strength of carbon fiber to increase the tensile strength and retard the cracks of the existing structures so that to increase the anti-crack performance and rigidity to realize the structural strengthening.

through the high pressure of the concrete and high strength of carbon fiber to increase the tensile strength and retard the cracks of the existing structures so that to increase the anti-crack performance and rigidity to realize the structural strengthening.

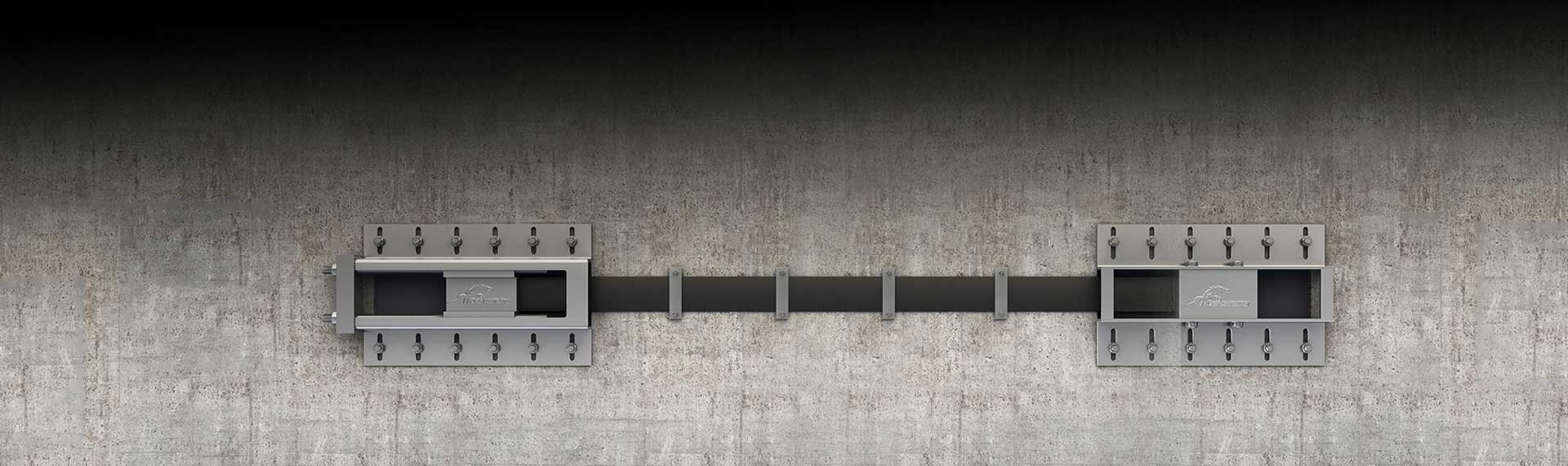

enable CFRP be in strain status when adhere CFRP with substrates. no bending or curve between bonding member and pulling direction, hence no peeling strain caused. high strength bolt ensure the fast fixing, which could be double secure to avoid damages caused by peeling and bonding.

enable CFRP be in strain status when adhere CFRP with substrates. no bending or curve between bonding member and pulling direction, hence no peeling strain caused. high strength bolt ensure the fast fixing, which could be double secure to avoid damages caused by peeling and bonding.

low shear strain, as lower increase of stress and strain of prestress member than that of no prestress member, less shear on epoxy than non prestress members, low possibility of bonding strength.

low shear strain, as lower increase of stress and strain of prestress member than that of no prestress member, less shear on epoxy than non prestress members, low possibility of bonding strength.

full mechanical self—lock, avoid failure because of epoxy aging, solve the problem of low shear of CFRP, ensure the system secure and long durability.

full mechanical self—lock, avoid failure because of epoxy aging, solve the problem of low shear of CFRP, ensure the system secure and long durability.

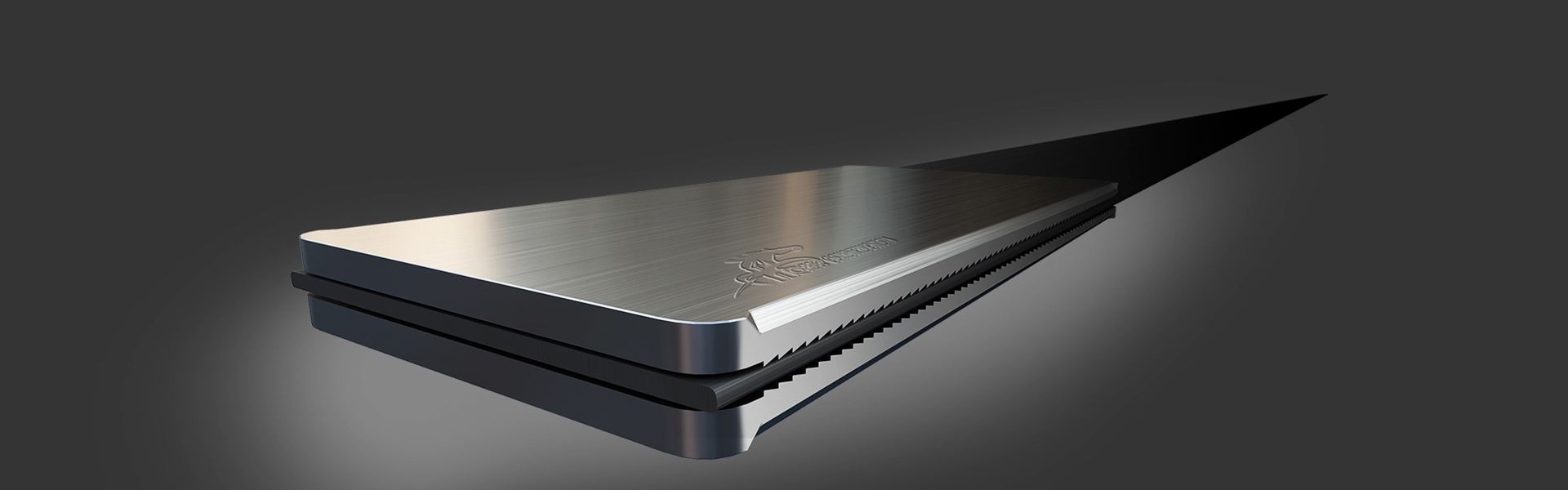

logical taper makes strong nipping strength, logical lean angle, gear depth and length, slab length, after hundreds of testing, suitable hardness, achieved minimum damages on CFRP.

logical taper makes strong nipping strength, logical lean angle, gear depth and length, slab length, after hundreds of testing, suitable hardness, achieved minimum damages on CFRP.

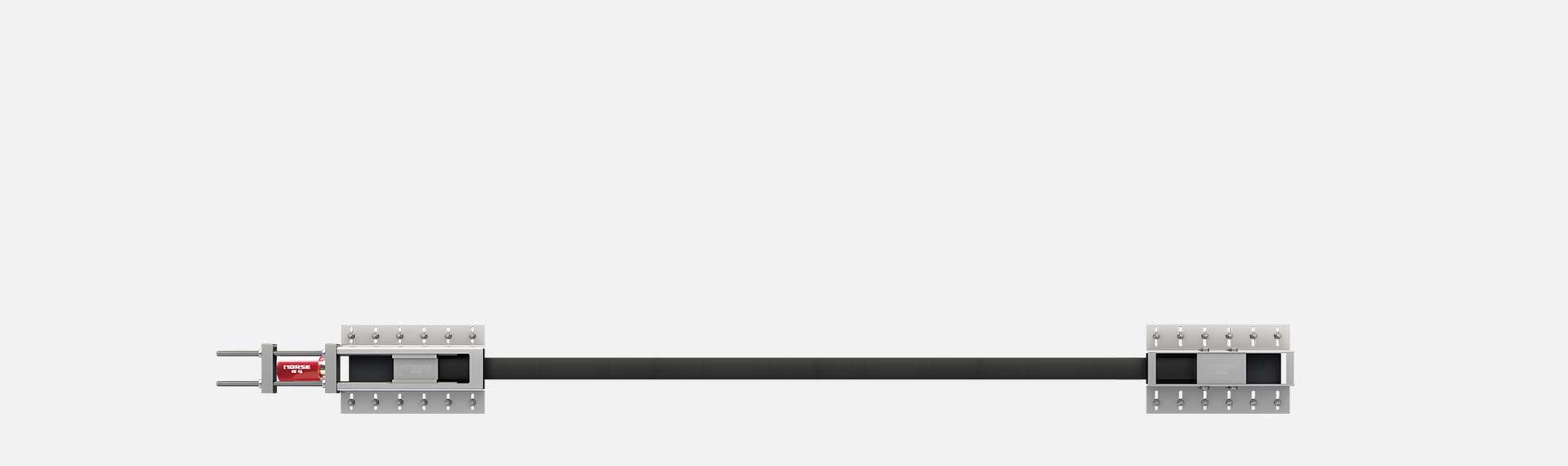

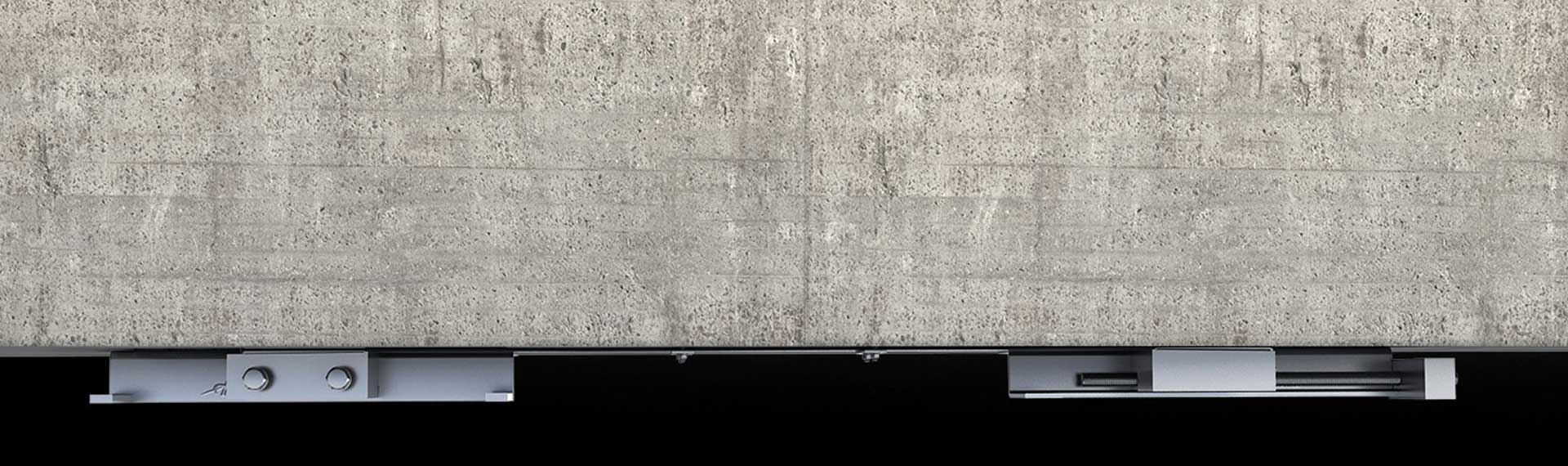

• HM pre-stressed FRP laminate system is composed of carbon fiber laminates, and anchoring device.

• through the clips make the stress to carbon fiber laminates, make the laminates anchoring to concrete permanently, and that will add the stress to the concrete in bending direction.

• the increasing stress can remove or retard the stress hysteresis of the added structures, make the existing crack reducing or even closed completely, so that to achieve real reinforcing.

• safe and reliable

• easy to install

• good economical

• reliable patent anchorage system

• suitable for large span beam slab of flexural reinforcement

• matching carbon fiber plate,adhesive,anchoring devices ensures the system matching

• Active strengthening, no stain lagging

• Reduce the cracks of the component effectively and slow the development of cracks

• Increase the crack resistance and rigidity of the component, increase the loading capacity of component

• Fully achieve the high strength property of carbon fiber, both new and original component be under loading.

Pre-stressed CFRP Laminate

![]() HM-3.0T carbon fiber laminate.pdf

HM-3.0T carbon fiber laminate.pdf

![]() HM-2.0T carbon fiber laminate.pdf

HM-2.0T carbon fiber laminate.pdf

![]() HM-1.2T carbon fiber laminate.pdf

HM-1.2T carbon fiber laminate.pdf

![]() HM-1.4T carbon fiber laminate.pdf

HM-1.4T carbon fiber laminate.pdf

| Pre-stress FRP strengthening system (patent number:ZL.2014.2.0115709.1) | |||

|

Prestress carbon fiber plate |

HM-1.2T |

Thickness | 1.2mm |

| Width | 50mm/100mm | ||

| Length | 100m/roll | ||

|

HM-1.4T |

Thickness | 1.4mm | |

| Width | 50mm/100mm | ||

| Length | 100m/roll | ||

|

HM-2.0T |

Thickness | 2.0mm | |

| Width | 50mm/100mm | ||

| Length | 100m/roll | ||

|

HM-3.0T |

Thickness | 3.0mm | |

| Width | 50mm/100mm | ||

| Length | 100m/roll | ||

|

Self lock anchorage |

HM-MJ100 | ||

| HM-MJ50 | |||

| HM-MJ20 | |||

| HM-MJ-G50 | |||

| Pre-stress Carbon Fiber Laminate Performance Parameters | |

| Tensile Strength ( MPa) | ≥2800 |

| Tensile Modulus(MPa) | ≥1.6×105 |

| Elongation(%) | ≥1.6 |

| Interlaminar Shear Strength(MPa) | ≥50 |

| Cohesive pulling strength with concrete(MPa) | ≥2.5 (Concrete cohesion damage) |

| Fiber volume fraction(%) | ≥65 |

| Anchorage Performance Parameters | |

| Steel Tensile Strength(MPa) | ≥345 |

| Stress Amplitude Difference(MPa) | 160 |

| 2 Million Fatigue Test Fmin(MPa) | 1120 |

| 2 Million Fatigue Test Fmax(MPa) | 1280 |

Prestressed CFRP laminate operatation process