Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

Slab strengthening, column strengthening, beam strengthening, wall strengthening, seismic strengthening.

| Cast-in-place slab

Prefabricated slab |

Externally bonded steel plate, fix chemical anchoring |

| Externally bonded carbon fiber reinfroced polymer(CFRP wrap) | |

| Newly added cast-in-place slab | Post installed rebar + angle steel support, or post installed rebar + shear reinforcement |

|

Insufficient bearing capacity of column compression normal section |

Enlargement of cross section, main reinforcement and stirrup |

| Externally bonded steel plate, steel jacketing | |

|

Continuous bonding of carbon fibers along the full length of the ground (circumferential girding) |

|

|

Insufficient bearing capacity of columns under compression |

The fiber direction should be perpendicular to the longitudinal axis of the column. |

|

Insufficient bearing capacity of column large eccentric compression |

The fiber direction is aligned with the longitudinal axis of the column |

|

Aseismic reinforcement of the ductility of a column |

Circumferential girth of ring bonding fiber composite as an additional stirrup |

|

Normal section reinforcement (water tower, water tank and closed structure) of tensile members |

The fiber composite is externally bonded to the concrete surface of the tensile part, and the direction of the fiber is consistent with the tensile direction. |

|

The outer steel plate is on the concrete surface of the tensile part, and the direction of the steel plate is consistent with the direction of the pulled steel bar. |

|

|

Newly added cast-in-place colum |

Main tendons of planting reinforcement + shear reinforcement and stirrup |

| Lack of bearing capacity of positive bending moment in beam | Enlarging column section |

| Externally bonded steel plate | |

| Externally bonded carbon fiber reinfroced polymer(CFRP wrap) | |

| Steel jacketing | |

| The insufficient bearing capacity of the negative bending moment in the end of the beam | Externally bonded steel plate |

| Externally bonded carbon fiber reinfroced polymer(CFRP wrap) | |

| Pouring the grouting material at the end of the beam with armpit | |

| The insufficient bearing capacity of the shear and oblique section shear in the end of beam | Externally bonded steel plate |

| Externally bonded carbon fiber reinfroced polymer(CFRP wrap) | |

| Steel beef leg | |

| Additional shear reinforcement |

| Deficiency of column ductility | Circumferential bonded fiber composites form circumferential girth as additional reinforcement. |

| Improvement of seismic structure by frame joint | Beam end steel plate armpit |

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

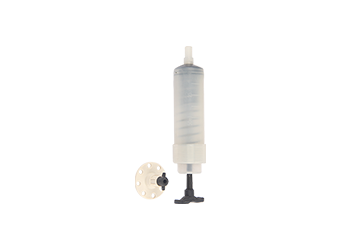

Volum: 75ML

Epoxy injctor is the tool to inject the epoxy into the crack.

Weight: 300g/sqm

Thickness: 0.167mm

Density: 1.8g/cm³

Packing: 100 meters/roll

Width: 100mm, 200mm, 300mm, 500mm or to be cu

Manuel dispenser gun

Imported high quaility

Specially designed for 390ml HM-500 injectable epoxy anchor adhesive.