Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

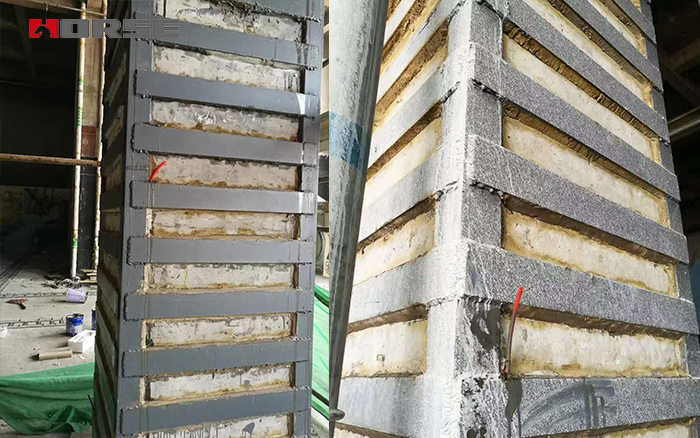

1.scaffolding 2.preparing the surface 3.installing the steel frame 4.sealing and setting gas vent 5.mixing and injecting the adhesive 6.curing and maintenance 7.examination 8.applying anti-corrosion measures

1.Scaffolding

2.Grinding on the concrete surface

3.Repair and leveling of concrete surface defects

4.Cleaning of concrete surface and angle steel surface

5.Polishing and removing rust on the surface of steel paste

6.Angle steel positioning on the surface of concrete

7.Welded flat steel bars around angle steel

8.Circumjacent edge of angle steel

9.Preparation of steel plate bonding adhesive

10.The special glue press is used to press the perfusion steel plate glue into the angle steel.

11.Structural adhesive curing

12.Field test

13.Cement mortar protection

(1) surface treatment of concrete and angle steel

Concrete surface treatment: first the concrete surface is roughly chiseled with chisel, then a steel wire brush is used to brush the loose surface of the surface, then the concrete surface is grinded and leveled with a sand turbine, and the water is cleaned with water to wipe the surface with industrial alcohol.

For the sticky surface of the old and very dirty concrete components, we should first use hard brushes to dip the high efficient detergent, brush off the surface oil scale pollutants, then chisel the weathered and loose layer carbonized layer, and then wear the paste surface to remove the 2~3mm thick surface until the new surface is completely exposed, and the powder is blown away with the oil free compressed air. After treatment, if the surface is serious and uneven, epoxy resin mortar can be used to repair it.

If the concrete surface is not very old and very dirty, it can be directly grinded to the adhesive surface, remove the 1~2mm thick surface, clean the dust and wipe the surface with acetone with skimmed cotton.

For the new concrete surface, first use the wire brush to brush the surface loose scum, then brush the surface with a hard brush, wash it with water, and then dry it completely.

For concrete members with larger moisture content or concrete members of the age of 3 months, the bonding strength of general resin adhesive on wet base will be greatly reduced, so artificial drying is still needed to meet the above requirements.

(2) surface treatment of steel

The surface of steel must be derusted and rough treatment. First, the surface of the steel plate is grinded with a steel wire brush on the surface of the steel plate to remove the rust until the metallic luster is exposed. Then the grinding wheel is used to grind the rough, the better the roughness is, the better the grinding road and the angle of the angle steel are perpendicular to the force, and then wipe clean with the degreased industrial alcohol. For the angle steel bonding surface, the following two methods should be adopted according to the degree of corrosion of angle steel:

The steel is not rusty or slightly rusty. It can be ground by sandblasting, abrasive cloth and grinding wheel until there is metallic luster. The better the roughness is, the better the grinding is perpendicular to the stress direction of the steel plate and wipe with acetone.

If the corrosion of steel is serious, it is necessary to soak 20min with appropriate hydrochloric acid, so that rust layer will fall off, then rinse with lime water, neutralize acid ions, and use grinding wheel to grind the grain road.

(3) special structure repair glue to repair non dense or defective parts

(4) fixed angle steel

The angle steel is fixed on the concrete surface according to the design requirements, and the 3 ~ 5mm gap is reserved between the angle steel and the concrete surface, so that the bond strength between the structure glue and the concrete has a bond strength, and the gums are reserved on both sides of the corner steel.

(5) welding of flat steel fixed plate

When the angle steel is fixed, the flat bar should be welded to the four corners of the frame column (beam) at the same time according to the size of the design requirements.

(6) circumjacent edge of corner steel

After installing the corner steel and the flat steel affixes, the corner steel is closed around the corner steel, and the top of the angle steel can not be closed so that the air is excluded when the glue is filled.

(7) preparation glue

Use the special pouring type sticky steel structure glue to prepare the proportions of a and B according to the prescribed proportion. The preparation should be carried out in strict accordance with the requirements of the product instructions, but due to the strong time limit of the glue, the field test should be carried out before use, and all the mechanical indexes are selected as the best ratio. Weighing according to the selected proportion, pour the two components of a and B into clean containers and stir them in the same direction until the color is completely uniform.

(8) the special glue press is used to press the perfusion sticky glue into the angle steel.

The structural glue is injected into the container of the glue filling machine to connect the reserved glue inlet, and the small structural air compressor is used to press the structural glue into the angle steel. The pressure can not be too large to prevent the phenomenon of swelling and leakage, and to observe the top of the angle steel at the top of the glue. If the rubber is found on the top, the structural adhesive is filled and the glue is observed at the top of the corner steel after 3~% minutes.

(9) curing

At present, the structural adhesives are cured at room temperature (20 degrees), 24h can be initially solidified, and 3D can be used by force. If the temperature is below 15 C, the low temperature curing glue or artificial temperature should be used. For small area reinforcement, it is generally heated with infrared light, and no disturbance to the steel plate during the curing period.

(10) anticorrosion treatment of steel plate surface

According to the design requirements, the high strength cement mortar is applied on the outer surface of the civil construction unit to prevent the abdomen.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Weight: 600g/sqm

Thickness: 0.333mm

Density: 1.8g/cm³

Packing: 100 meters/roll

Width: 100mm, 200mm, 300mm, 500mm or to be cus

Part A (Epoxy): 20kg

Part B (Hardener): 1kg

Mix Ratio: Part A: Part B=20:1

Barrel A Size: 30*30*37cm

Barre

Type: HM-500

Volume: 390ml

Mix Ratio: 3:1

Color: Red or Black

Density: 1.5±0.1g/cm³

Packin