Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

The successful implementation of this reinforcement scheme provides engineering examples and strong evidence for the application of CFRP reinforcement technology in shear-compression damage of reinforced concrete beams.

General Situation of Reinforcement Engineering

The shrinkage of main shaft in Jining No.3 Coal Mine was completed in 1997. In 2006, the deformation of the steel column supporting the lock beam caused by the sinking of the main shaft tower resulted in the top pressure of the lock beam, which resulted in the shear and compression failure of the reinforced concrete lock beam with a span of 7 m, a height of 800 mm and a width of 300 mm. There are 8 oblique cracks on the beams with a width of 0.3 mm and a maximum of 1.8 mm. Most of the cracks are permeable. After testing by qualified structural safety appraisal departments, reinforcement measures must be taken.

Selection of Reinforcement Scheme

Based on the stress condition, failure state and field practice, the conventional strengthening schemes, such as enlarging section method, enclosing steel reinforcement method, prestressing reinforcement method and changing the stress system reinforcement method, are demonstrated and compared with the CFRP reinforcement schemes economically. Finally, the reinforcement scheme of CFRP is determined.

Thought of CFRP Reinforcement Design

(1) Unloading: Eliminate the compression and buckling deformation of the steel column, relieve the deformation stress, achieve the purpose of unloading the lock beam, so as to restore the lock beam to the original stress state.

(2) Repair of shear-compression damage cracks: In order to improve the integrity of the damaged lock beams, restore the use function of the beams, improve the durability and prevent the corrosion of steel bars in the beams, AB-grouting resin was used for drilling and grouting eight octagonal inclined cracks on the beams.

(3) Confirmation of strengthening bearing capacity: The flexural and shear bearing capacity of the strengthened beams should reach the original design bearing capacity. According to the test results, the longitudinal reinforcement and stirrups of the beam are not destroyed, so the flexural bearing capacity meets the requirements; while the shear bearing capacity of the beam is greatly reduced or lost due to the shear compression failure of concrete, and all the shear force is borne by the stirrups. Therefore, the reinforcement is shear reinforcement. The shear capacity of the concrete in the reinforcement design does not take into account the shear capacity of the lock beams, but only the shear capacity of the stirrups in the lock beams. The insufficient part of the shear capacity is borne by carbon fiber sheets.

Through calculation, the shear reinforcement method is “U” hoop spacing is 0, full paste distribution, and the number of paste layers is 4.

Concluding remarks

After the reinforcement construction is completed, the structural safety appraisal department checks that the construction quality meets the requirements of the current national standards, matching acceptance specifications and technical regulations, and the bearing capacity of the structure meets the original design requirements. The successful implementation of this reinforcement scheme provides engineering examples and strong evidence for the application of CFRP reinforcement technology in shear-compression damage of reinforced concrete beams.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Part A(Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

Barrel B

Volum: 75ML

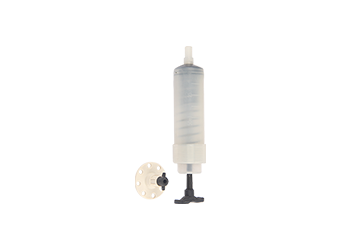

Epoxy injctor is the tool to inject the epoxy into the crack.

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Density:1.6±0.1g/cm³

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

See more >