Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

In view of the lack of prestressing steel wire in the prestressing hollow floor, several reinforcement schemes are analyzed and selected according to their characteristics. Decide to choose the sticky carbon fiber cloth method.

Renovation of Dangerous Buildings and Selection of Reinforcement Methods

Four seven-storey concrete frame residential buildings (buildings) in a city, such as A, B, C and D, are included in the renovation project of dangerous buildings, in which two parts of C and D adopt PC pre-stressed hollow floor. Hollow slab size: L. B. H = 3300 * 600 * 100mm, C25 concrete strength grade, 6 < 10 low carbon steel wire. However, due to the insufficiency of prestressing steel wire allocation (reinforcement ratio) in the production process, the ultimate bearing capacity (bending moment) is reduced and the deflection is increased. The design allows deflection L0_200, i.e. less than 15 mm. The measured deflection before reinforcement is 17-18 mm, which is too large. In view of the fact that the floor has been installed, the reinforcement treatment is chosen.

In view of the lack of prestressing steel wire in the prestressing hollow floor, several reinforcement schemes are analyzed and selected according to their characteristics. Decide to choose the sticky carbon fiber cloth method.

Carbon fiber cloth is a new type of composite material. It is widely used in the reinforcement of civil engineering structures because of its excellent properties such as light weight, high strength, high elastic modulus, corrosion resistance, convenient construction, time-saving and labor-saving.

Carbon fiber reinforced concrete (CFRP) is a new technology widely used in concrete structures, which is fast and reliable. And carbon fiber cloth is light, its density is 1/4 of steel, and its tensile strength is about 15 times the yield strength of steel Q235. The wrapping of carbon fiber sheet can improve the deformation performance of high strength concrete, greatly increase the stiffness of members, and achieve the purpose of reducing deflection. It is an ideal material for strengthening the normal section of pre-stressed floor with flexural members.

The technical principle of CFRP reinforcing and reinforcing pre-stressed floor slab is not included in the Technical Specification for Reinforcing Concrete Structures because CFRP reinforcing and reinforcing pre-stressed floor slab is a new technology. This paper mainly discusses the principle of remedial measures for excessive deformation caused by insufficient reinforcement of the original component.

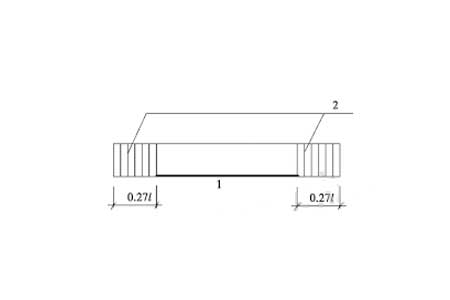

The direction of bonded CFRP sheet is parallel to the axis direction of prestressing hollow floor. Strengthened members are shown in Fig. 1

Construction Procedure and Technical Points

(1) The surface of the base course of concrete members should be polished and cleaned up, and the strength of the base course should be greater than or equal to 20 MPa in order to prevent peeling.

(2) When the plate is strengthened by bending, CFRP extends to the end of the plate as far as possible. The scheme of multi-strip dense cloth with carbon fiber cloth is adopted.

(3) Carbon fibre sheet_type transverse pressing strip should be set at the end of the extension length of carbon fibre sheet and at both sides of the action point of concentrated load, and the number of bonding layers of carbon fibre sheet should be one layer, so as to make full use of its function.

(4) When the overlap of CFRP is required along the direction of force, the overlap length should not be less than 150 mm, and the overlap positions of each layer are staggered.

(5) On-site acceptance after the completion of construction is mainly to evaluate the bond quality between CFRP and concrete. If the bond area is less than 90%, the bond will be invalid and need to be re-constructed.

Comments on Reinforcement Effect

Based on the above principles, the reinforcement design of the members is carried out. According to formula (4), the area conversion of carbon fiber sheet is carried out. After strengthening, a series of tests are carried out on the members, and the ideal effect of greatly increasing the stiffness and controlling the deflection within the allowable range is obtained.

After reinforcement, the actual bearing capacity of members is increased by 18% compared with the design allowable value, reaching 11.68 kn/m2.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Two batteries, each one 4800 mAh

6 Speed mode

Portable design

Best for Large scale anchoring

Weight: 600g/sqm

Thickness: 0.333mm

Density: 1.8g/cm³

Packing: 100 meters/roll

Width: 100mm, 200mm, 300mm, 500mm or to be cus