Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

The project has been effectively controlled in all aspects of CFRP reinforcement to ensure the quality of reinforcement. After carbon fiber reinforcement, the design intention has been achieved through joint acceptance by all parties, and it has received unanimous praise from Party A and supervision.

Basic information

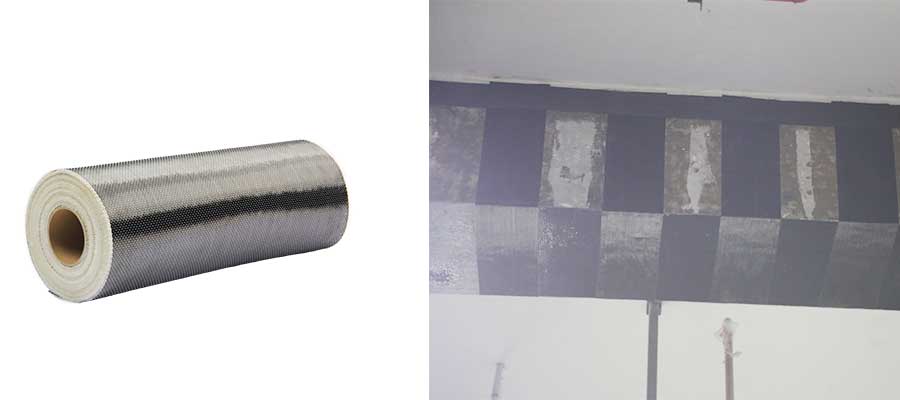

The construction time of a workshop project was in the 1990s, and a large number of cracks appeared on the floor of some structural beams and slabs. After checking and recalculating by the designers, it is considered that the beams should be strengthened by pasting CFRP. The main reinforcement content is to paste 300 g/m2 carbon fiber sheet on the beam.

Construction process

Construction preparation, crack treatment, alignment, base treatment, painting leveling glue, painting primer, carbon fiber cloth pasting, maintenance, surface treatment

Surface treatment of concrete

(1) The deteriorating parts of the surface of the condensate, such as spalling, empty drum, honeycomb and corrosion, should be chiseled out, and the large area of the inferior layer should be repaired with designated materials after chiseling out.

(2) The sealing treatment of the grouting joints should be carried out at the crack site first according to the design requirements. Epoxy resin pressure grouting is used for grouting.

(3) Using diamond angle grinder to remove impurities such as floating slurry and oil stain on the surface of concrete, the concrete of the base surface of components should be polished smoothly, especially the protruding part of the surface, until a new structural surface is seen;

(4) If there is more dust on the surface of concrete to be cleaned up, oil-free compressed air should be used to blow out the dust.

(5) Use cotton silk to dip in acetone and wipe the polished concrete surface clean.

(6) Check the surface of concrete again. If there is a depression, it should be filled with the specified material to leveling.

(7) Report to the person in charge of the scene for inspection

Cutting of Carbon Fiber Cloth

(1)When pasting carbon fibre cloth, it is necessary to cut the finished carbon cloth into the dimension of drawing design. Carbon fibre cloth is laid on the flat surface. Carbon fibre cloth is cut along the fiber direction with a wallpaper knife according to the design dimension (requiring sharp blades). The remaining parts can be spliced together, but the lap size should be guaranteed to be greater than 100 mm.

(2) Carbon fiber cloth is a unidirectional force-bearing material, along the direction of the fibers for the direction of force, when cutting, special attention should be paid to the direction, avoid oblique cutting of the fibers. When cutting, the drawing phenomenon should not appear as far as possible.

(3) When cutting and using carbon fiber cloth, we should keep away from power supply as far as possible, especially high voltage power supply and transmission line.

Brushing primer

(1) Carbon fibre cloth should be kept away from fire and avoid direct sunlight;

(2) The preparation of base glue.

Brush leveling glue

(1) The preparation of leveling glue.

(2) Leveling glue should be used to fill hollow parts of concrete surface, and leveling glue should be used to fill parts with poor height, such as form work joints, so as to minimize the height difference.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Density:1.6±0.1g/cm³

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

See more >

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Consumption Ratio: 0.6-0.9kg/sqm

See more >

Part A: Modified Epoxy (20kg)

Part B: Hardner(10kg)

Mix Ratio: A:B=2:1

Consumption Ratio: 0.2-0.3kg/sqm

Barrel A Size: 30*30