Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

Right evaluation of the bond behavior between corroded reinforcement and concrete wrapped with CFRP is a chief problem to confirm the effect of CFRP confinement.

Main factors affecting bond performance between corroded steel bar and concrete

1. Types of reinforcement

Under the same conditions (thickness of protective layer, corrosion rate, FRP constraint), the peak bond strength of threaded bar specimens is significantly higher than that of smooth round bar specimens, which is about twice the peak bond strength of smooth round bar specimens. Moreover, the slip of the reinforced bar is larger than that of the round bar when the peak pull-out load is reached for the specimens of the threaded bar.

2. Thickness of protective layer

(1) Under the same conditions (steel bar type, corrosion rate, fiber cloth restraint), when the thickness of protective layer increases from 40 mm to 60 mm, the peak bond strength of most corroded steel bar increases by 7.0%-51.2%.

(2) For corroded reinforced bar specimens, the slip of reinforced and unreinforced specimens increases with the increase of the thickness of the protective layer under the peak pull-out load. For corroded round steel bar specimens, the slip under peak pull-out load is basically equal when the thickness of protective layer changes. However, after the peak pull-out load, the descending section of the bond-slip curve of the specimens with large thickness of the protective layer obviously slows down, while the descending section of the bond-slip curve of the reinforced specimens changes little with the thickness of the protective layer.

3. Corrosion rate of reinforcement

(1) When the corrosion rate is less than 5%, the bond strength of unreinforced corrosion specimens increases by about 7% compared with the peak bond strength. The bond strength of reinforced corrosion specimens increases by about 5% compared with the peak bond strength. This is because the concrete protective layer has no obvious effect when the corrosion degree of steel bar is small, and the bond between steel bar and concrete is stronger due to the rust expansion of steel bar, which leads to a slight increase in the peak bond strength.

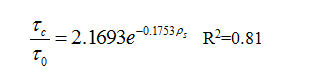

(2) When the corrosion rate is more than 5%, the peak bond strength of corroded specimens decreases gradually with the increase of the corrosion rate. This is because the mechanical biting force between steel bar and concrete decreases due to the corrosion of transverse ribs when the corrosion degree of steel bar is large. Moreover, the rust expansion of steel bars has a certain damage effect on the concrete protective layer, so the peak bond strength decreases. Based on the test results of other scholars, the relationship between the specific peak bond strength and the corrosion rate of reinforcing bars for specimens whose corrosion rate is more than 5% is fitted as follows:

4. Confined with CFRP

(1) Under the same conditions, the peak bond strength of CFRP strengthened specimens is higher than that of their standard specimens. However, when the corrosion rate of steel bar is small, the effect of CFRP restraint on the peak bond strength of specimens is small. Before reaching the peak drawing load, the transverse expansion deformation of the specimens is small, and the restraint effect of CFRP is not significant. When the corrosion rate is high, the restraint force of CFRP is increased by steel corrosion.

(2) The unreinforced specimens enter the descending section or splitting failure immediately after reaching the peak pull-out load. Before reaching the peak pull-out load, the pull-out load of the reinforced specimens keeps at a higher level, and eventually reaches the peak pull-out load slowly. Because the stress of CFRP increases after the longitudinal splitting crack appears, the crack development is controlled, and the load can continue to grow slowly.

(3) Compared with the unreinforced specimens, the downward section of the strengthened specimens has a gentle slope, and the corresponding ultimate bond strength is also greater than that of the unreinforced specimens, which indicates that the CFRP reinforcement is more effective in slowing down the decline rate of bond stress and maintaining bond stress.

Conclusion

1) The splitting of concrete protective layer is restrained in the process of drawing, and the failure mode is changed from splitting failure to pulling out failure, and the bond slip curve appears a descending section after strengthening.

2) The types of reinforcing bars significantly affect the peak bond strength of corroded steel bar specimens. Under the same conditions (thickness of protective layer, corrosion rate, carbon fiber cloth restraint), the peak bond strength of threaded steel bar specimens is about twice that of smooth steel bar specimens.

3) The thickness of protective layer is one of the main factors affecting the peak bond strength of corroded steel bar specimens. Under the same conditions (steel bar type, corrosion rate, carbon fiber cloth restraint), when the thickness of protective layer increases from 40 mm to 60 mm, the peak bond strength of most corroded steel bar specimens increases by 7.0%-51.2%.

4) Under the same conditions (reinforcement type, protective layer thickness, carbon fiber cloth restraint), when the corrosion rate of reinforcement is less than 5%, the specific peak bond strength of unreinforced corrosion specimens is increased by about 7%, and that of reinforced corrosion specimens is increased by about 5%. When the corrosion rate of steel bars is slightly higher than 5%, the peak bond strength of corroded steel bars decreases slightly.

5) When the corrosion rate of steel bar is less than 5%, the CFRP restraint has little effect on the peak bond strength of specimens, but the CFRP restraint slows down the decline of the bond-slip curve of specimens, and increases the ultimate bond strength, which indicates that the CFRP restraint is more effective in slowing down the decline rate of bond stress and maintaining bond stress.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Type: HM-500

Volume: 390ml

Mix Ratio: 3:1

Color: Red or Black

Density: 1.5±0.1g/cm³

Packin

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Consumption Ratio: 6-7kg/sqm

Bar