Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

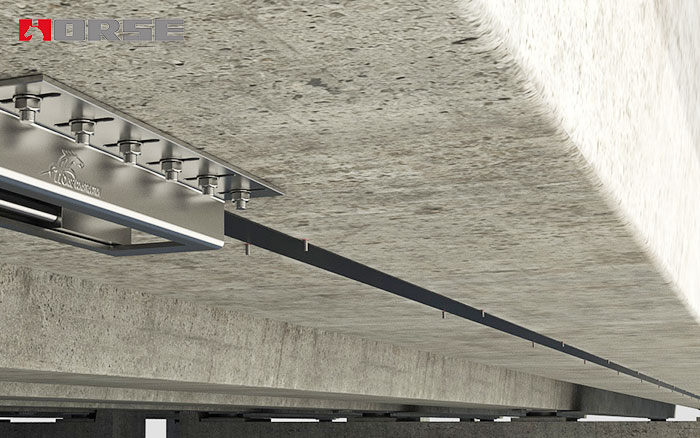

A certain pre-stress is applied to the carbon fiber plate, and a certain strength is exerted in advance, so that the high-strength performance is fully utilized, which is an active reinforcement method, and the reinforcement effect on the structure is very obvious.

Prestressed CFRP reinforcement system on the market generally consists of three parts: CFRP plate, anchorage and CFRP glue.

To achieve a certain reinforcement effect, the three parts need to work together.

However, as with any other reinforcement method, although the reinforcement effect of pre-stressed carbon fiber plate is obvious, various problems will inevitably arise in the construction operation.

1. Transverse or Longitudinal Fracture of Prestressed Carbon Fiber Plate

There are two reasons for the fracture of prestressing carbon fibre plate:

First, the quality of the pre-stressed carbon fiber plate material is not up to standard. Prestressed carbon fibre sheets are formed by soaking and hardening carbon fibers arranged in the same direction with resin, and have super high strength. At a certain length, the bending capacity of the pre-stressed carbon fiber sheet without being damaged actually depends on the bonding material and production process. There are different kinds of defects on the surface of prestressing carbon fibre sheet and large straightness deviation, which will cause stress concentration, uneven stress or damage of anchorage end in the process of high stress tension of carbon fibre sheet. In the stress state of more than ten or even more than twenty tons, it is easy to be destroyed, which brings a lot of hidden dangers to the safety of the operation site.

Second, the construction or die installation causes the transverse shear force of the prestressing carbon fiber board to be too large, or the longitudinal eccentric force of the prestressing carbon fiber board. The strength of prestressing carbon fibre sheet is anisotropic, and it is easy to cause carbon plate fracture due to improper operation in construction.

2. Slipping of Prestressed Carbon Fiber Plate

Because the gap between the clamp and the splint is too large, the clamping force is insufficient, which results in the slippage of the pre-stressed carbon fiber sheet when the pre-stressed carbon fiber sheet is applied. The slip of prestressing CFRP affects the application of prestressing force, which is not conducive to the reinforcement of the structure.

3. Failure of Limiting Frame

Limit frame plays a very important role in the effect of tension and anchorage. If the strength of screw used is insufficient to cause fracture or deformation of limit frame, which results in failure of limit frame, it can not reinforce the structure.

In the installation of prestressing carbon fiber board, the anchor block fails due to the wrong installation of anchor block.

5. The Jack Problem

Jack is a special device used for tension of prestressing carbon fibre sheet. Oil leakage or over travel tonnage of the jack will affect the construction. Therefore, the parameters of the jack should be strictly checked before use, and overpressure and overload should be avoided. Check the oil quantity of the oil pump before tensioning, and make the jack run several times to empty the jack and the air in the tubing.

In summary, the problems in the construction of pre-stressed carbon sheet are mainly caused by the quality of the material itself or improper construction.

Shanghai Horse Construction has been engaged in research and development, production and sales of reinforcing materials for more than ten years. It has developed and produced reinforcing materials for prestressing carbon fiber plate. The wedge anchorage developed by Hummer can achieve no failure under the condition of ultimate failure of prestressing carbon fibre plate. And under 2 million fatigue load tests, the prestressing carbon fiber plate did not break and fatigue failure, and there was no relative slip between anchorage and prestressing carbon fiber plate.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Part A (Epoxy): 20kg

Part B(Hardener):10kg

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

Bar

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Consumption Ratio: 6-7kg/sqm

Bar

Part A (Epoxy): 15kg

Part B (Hardener): 5kg

Mix Ratio: Part A: Part B=3:1

Barrel A Size: 30*30*37cm

Barre