Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

It is very effective to reinforce the cracked brick walls with CFRP sheets. The ultimate load of cracked wall strengthened with CFRP is significantly higher than that of unreinforced wall.

The technology of Strengthening Masonry Structure with CFRP has the advantages of high strength, high efficiency, convenient construction, good durability, no increase of weight and volume, wide application and so on. It has a broad application prospect in China. In this paper, the related research on the reinforcement and repair of the cracked brick masonry structure with CFRP is carried out. The test proves that the method can easily and effectively solve the problems of building wall cracks in the buildings that have plagued the society at present.

Test situation

Design and manufacture of 11 specimen

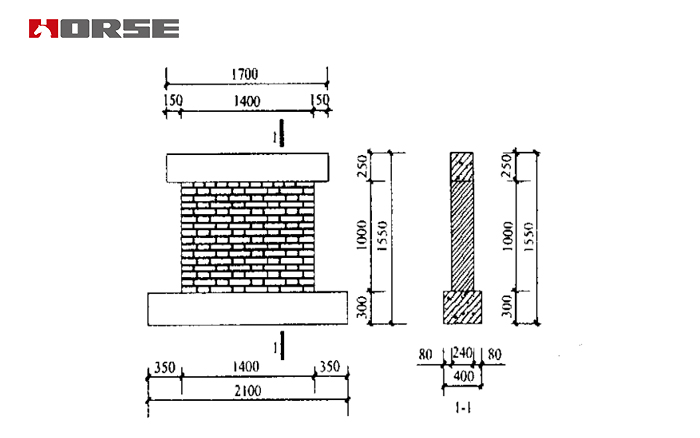

The height width ratio of the specimen is 1: 114, the wall thickness is 240mm, width 1400mm, and height 1000mm. When the specimen is made, the wall is made of MU10 brick and M10 cement mortar, and the upper and lower beams are C30 concrete. The vertical compressive stress is 0 2MPa = 11, and the specimen size is shown in Figure 1.

Reinforcement scheme for test parts

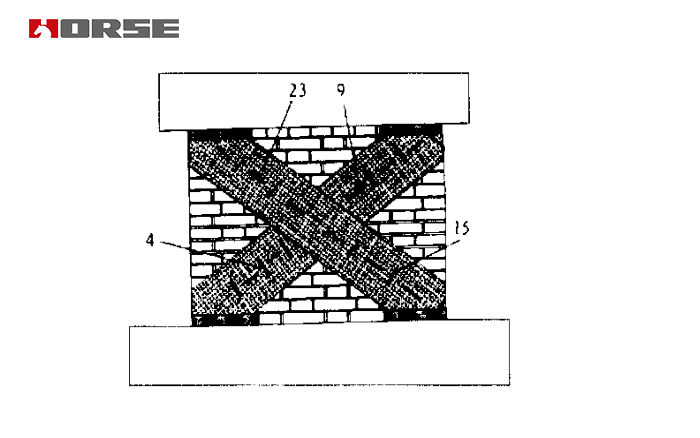

he specimen Wall 22 was cracked. First, the positive load is applied to the wall. When the loading to the cracking load (212kN), the brick wall suddenly cracks (the corresponding cracking displacement is 21 0mm) and forms a slanting crack quickly. As shown in Figure 2, the crack is about 01 25mm at the width of the crack. At this point, some cracks are closed and the width of the crack is about 011. Mm.

Strengthening by carbon fiber reinfroced polymer(CFRP). Double side sticking carbon fiber fabric , the width is 300mm, “X” shape, both upper and lower ends are anchored.

| Wall | f1(Mpa) | f2(Mpa) | Loading direction | Cracking load | Ultimate load | Dehiscence displacemen | Maximum tensile stress of CFRP | ||||

| Experimental value | Increase the degree value | Experimental value | Increase the degree value | Experimental value | Increase the degree value | ||||||

| Wall 21 | 11164 | 16189 | Average | 224 | – | 224 | – | 3107 | – | ||

| Wall 22 | 11164 | 16189 | Positive | – | – | 276 | 2312 | 810 | 16016 | 4323 | 1519 |

| Negative | 368 | 6413 | 368 | 6413 | 1114 | 27113 | 3392 | 545 | |||

Conclusion

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Thickness:1.2mm, 1.4mm, 2.0mm, 3.0mm

Density: 1.6g/cm³

Packing: 100 meters/roll

Width: 50mm, 100mm or to be custo

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

Barrel B Size: 25*25

Two batteries, each one 4800 mAh

6 Speed mode

Portable design

Best for Large scale anchoring