Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

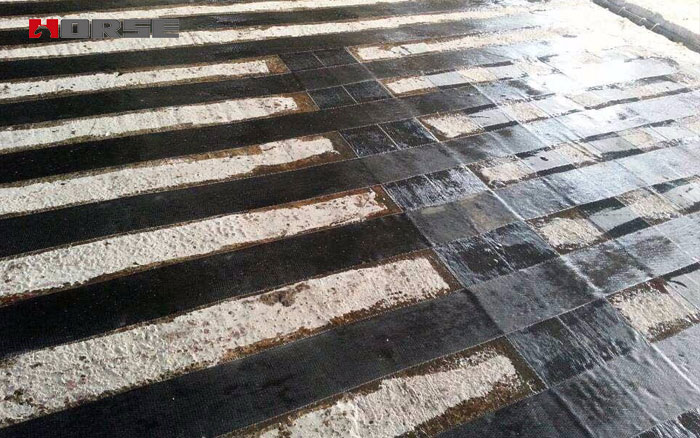

Furthermore, FRP fabric is pasted at the bottom of the floor with a certain spacing, so that some floors are covered by FRP, while others are not.

In engineering practice, whether it is due to the increase of floor load or structural modification and adjustment, there are many cases that need to be strengthened, which are very extensive. Unfortunately, although there are a lot of research materials for the use of FRP beam strengthening, but for reinforced concrete slabs, this study is indeed very poor.

Karbhari, a researcher, believes that it is not feasible to directly translate the research results of beams into the design and analysis of slabs. First, the stress state of the plate is bidirectional, and the stress state of the beam is unidirectional. In addition, the floor does not have shear reinforcement like beams. Furthermore, FRP fabric is pasted at the bottom of the floor with a certain spacing, so that some floors are covered by FRP, while others are not.

However, many researchers have pointed out that it seems reasonable to use the traditional method of studying reinforced concrete beams to analyze the reinforced concrete slabs strengthened by FRP in the absence of research results. Whether the floor is a one-way or two-way slab, even in a design project in Elhassan, there is a girderless floor. Of course, they also acknowledge that FRP application in reinforced concrete slabs is currently at an immature stage, there are still many experimental and theoretical analysis work to be completed, as well as the establishment of appropriate codes and regulations.

On the other hand, some basic conclusions are accepted by the vast majority of researchers in this field:

According to the different properties of FRP fabric and the different ways they are bonded, the improvement of floor bending moment bearing capacity is different, and the maximum can be increased to nearly 300% (Karbhari, 1999).

After the floor is strengthened with FRP fabric, the failure mode will be greatly changed. The failure mode of reinforced concrete slabs is ductile tensile-buckling failure of steel bars, while the ductility of reinforced slabs is greatly reduced. The main manifestation is that FRP material suddenly peels off the slabs or FRP material suddenly breaks (Karbhari, 1999).

They all recommend that transverse FRP strips be appropriately configured, as in ordinary reinforced concrete slabs, because a single directional arrangement is not the most economical and effective (Karbhari, 1999).

As far as the net spacing of FRP bar is concerned, as long as the net spacing is kept below 250 mm to 300 mm, the cracking position and failure mode of the floor during failure have little to do with it (Ichimasu, 2000; Karbhari, 1999). More research is needed, and Tann suggests that the maximum net distance should be 2.5 h0, where H0 is the distance from the center of the bottom reinforcement to the roof. Or if transverse FRP strips such as distributed steel bars are used, the net spacing can be appropriately enlarged, but these transverse FRP strips should be glued to the innermost side. In terms of construction sequence, these transverse FRP strips should be constructed first, then longitudinal (Tann et al. 2001).

At present, no material can show that external bonded FRP fabric can enhance the shear capacity of reinforced concrete slabs (Tann et al. 2001).

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Consumption Ratio: 6-7kg/sqm

Bar

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

Bar

Part A (Epoxy): 20kg

Part B (Hardener): 1kg

Mix Ratio: Part A: Part B=20:1

Barrel A Size: 30*30*37cm

Barre