Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

Common structural strengthening methods for beam, column, slab: sticking steel plate, bonded FRP composite materials, post installed anchoring, enlarged section

Slab strengthening

| Cast-in-place plate

Prefabricated plate |

Sticking steel plate +d10 anchor bolt |

|

Bonding carbon fiber reinforced polymer FRP composites |

|

| New cast-in-place slab |

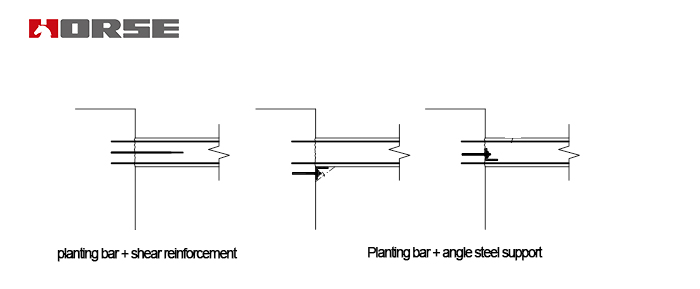

Post installed anchoring with injectable mortar + angle steel support, planting bar + shear reinforcement |

injectable mortar

| Insufficient bearing capacity of column under normal pressure | Increase section, main reinforcement and stirrups. |

| Wet method of externally bonded steel: modified epoxy adhesive infusion + protective coating (cement mortar plaster) | |

| Continuous bonding of carbon fibers along the full length of the ground (circumferential girding) | |

| Insufficient bearing capacity of inclined section under column compression | CFRP strengthening, the fiber direction should be perpendicular to the longitudinal axis of the column. |

| Insufficient bearing capacity under large eccentric compression | CFRP strengthening, the fiber direction is aligned with the longitudinal axis of the column. |

| Column ductility insufficient seismic strengthening | CFRP strengthening, the circular bonding and bonding fiber composite material forms the circumferential girth as the additional stirrup. |

| Normal section reinforcement (water tower, water tank and closed structure) of tensile members | The fiber composite is externally bonded to the concrete surface of the tensile part, and the direction of the fiber is consistent with the tensile direction. |

| The outer steel plate is on the concrete surface of the tensile part, and the direction of the steel plate is consistent with the direction of the pulled steel bar. | |

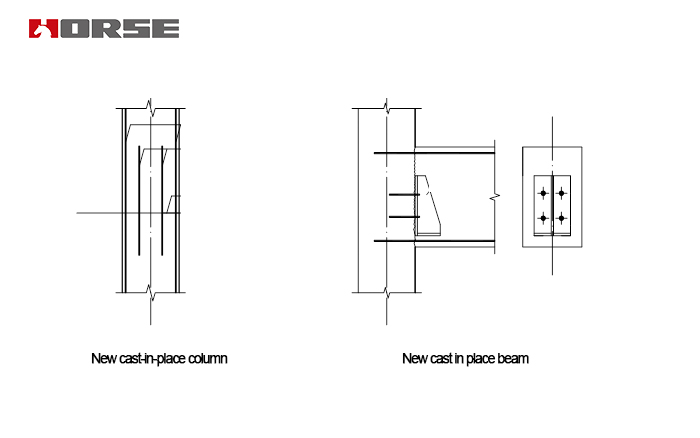

| New cast-in-place column | Planting steel bar main reinforcement + shear reinforcement + stirrups. |

| Insufficient bearing capacity of the beam moment | 1. enlarging the cross section to form the composite beam, planting the main reinforcement and the stirrup |

| 2. externally bonded steel | |

| 3. bonding FRP composites | |

| 4. sticking steel plate | |

| Insufficient bearing capacity of the negative bending moment at the end of the beam | 5. bonding FRP composites |

| 6. sticking steel plate | |

| 7. grouting the end of the beam with armpit, adding the axillary inclined bars and stirrup | |

| Insufficient shear bearing capacity of beam end and oblique section | 8. bonding FRP composite hoop |

| 9. stick steel plate hoop | |

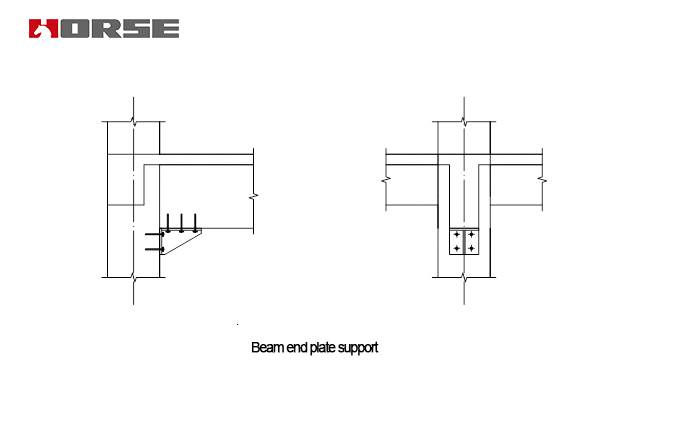

| 10. add steel corbel | |

| 11. additional shear reinforcement | |

| Adding concrete beams | 12. planting steel bars with positive and negative main reinforcement, and Liang Duan setting up steel corbel. |

Seismic strengthening

| Insufficient column ductilit | Circumferentially bonded fiber composite material constitutes a circumferential bundle, as an additional stirrup |

| Frame joints improve seismic construction measures | Beam end plate support |

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Weight: 200g/sqm

Thickness: 0.111mm

Density: 1.8g/cm³

Packing: 100 meters/roll

Width:100mm, 200mm, 300mm, 500mm or to be custo

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

Barrel B Size: 25*25

Weight: 300g/sqm

Thickness: 0.167mm

Density: 1.8g/cm³

Packing: 100 meters/roll

Width: 100mm, 200mm, 300mm, 500mm or to be cu