Solutions

Horse Construction business range tend to all over the world and service for thousands clients with products, technical,construction specialized guidance, and we witness the Chinese reinfocing brand's togther with them.

The tensile strength of the tow is very stable, the dispersion is small, and the coefficient of variation is below 5%. It is easy to control the performance and quality of the tow effectively in the process of production and use.

First, let’s know about the classification of carbon fiber.

Carbon fibers are classified into 3 categories according to their main raw materials.

Only PAN can meet the safety and durability requirements of load-bearing structures.

The K

The K number is larger than 12, but the carbon fiber which is not more than 24 is still in the range of small tow fiber.

Why use small PAN tow fiber for structural reinforcement?

The tensile strength of the tow is very stable, the dispersion is small, and the coefficient of variation is below 5%. It is easy to control the performance and quality of the tow effectively in the process of production and use. However, the tensile strength of large tows is unstable, the coefficient of variation is as high as 15-18%. The reliability of large tows is poor, and there are more phenomena such as carbon fiber adhesion and broken wires. This will affect the strength and stiffness, reduce the performance, and the performance will be more dispersive, which can not be used as reinforcement materials for load-bearing structures.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Type: HM-500

Volume: 390ml

Mix Ratio: 3:1

Color: Red or Black

Density: 1.5±0.1g/cm³

Packin

Volum: 75ML

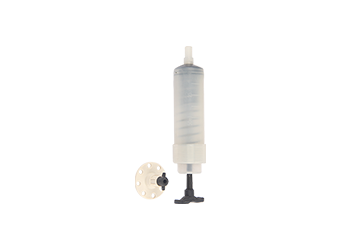

Epoxy injctor is the tool to inject the epoxy into the crack.

Part A (Epoxy): 20kg

Part B (Hardener): 10kg

Density:1.6±0.1g/cm³

Mix Ratio: Part A: Part B=2:1

Barrel A Size: 30*30*37cm

See more >